01/05/2023

Press Realease - PAYPER focuses on digitalization, accuracy and performance.

PAYPER stands for accuracy, control and performance

Accuracy

Weighing has been at the centre of interest in PAYPER's R&D&I department ever since the first weighing device was designed in 1973. In line with the ongoing commitment to weighing accuracy, PAYPER will present MSX: a new dynamic weight controller. It ensures maximum accuracy at high bagging speeds, being one of the most accurate weighing systems in the bagging industry. Accredited by official metrology institutions, it is specifically designed for the bagging of all types of solid products: granules, flakes and fine powders.

Control

Pulsar ensures full control of the production processes with a single click. This new cloud-based software solution enables bulk good producers to digitalize their bagging lines taking their production to the next level.

At PACK EXPO International in Chicago in 2022 PAYPER introduced the Pulsar-S, to enhance customers' after-sales-service experience. We are now introducing Pulsar M at the main meeting point for the packaging industry worldwide, Interpack 2023.

This all-in-one digital solution allows advanced management of production and service.

Pulsar S: Smart Customer Service and Maintenance

Make the most of your production line with Pulsar S. The different modules allow plant managers, maintenance managers and operators to work together to increase the lifetime and effectiveness of the bagging line machinery.

Among other actions, it is possible to perform:

Predictive Maintenance: risk management, task scheduling and tutorials to reduce maintenance costs and machinery downtime.

Quick spare parts management: orders, stock and deliveries.

Easier Customer Service communication: Omnichannel support.

Remote training and technical support: using augmented reality.

Data-driven decisions: real-time KPIs and analytics.

Pulsar M: Future-proof production management

Pulsar M is a cloud-based software solution for the collection, visualization and analysis of data from complete bagging lines: from dosing to warehouse management.

Among other functions, it is possible to access:

Overall Equipment Efficiency (OEE) measurement.

Alarm management: Step-by-step indications.

Traceability: batch management.

Monitoring: The status of every machine in the line can be monitored from any one of them.

Performance

PAYPER designs and manufactures high-performance bagging lines for industry leaders: Turnkey projects including dosing, weighing, bagging, palletizing and overwrapping.

Dosing and weighing: Wide range of dosing systems that adapt to the size, shape and fluidity of the product: gross or net weight, free-flowing or not, powdery, flakes or granulates.

Bagging: High-performance automatic bagging machines for open-mouth bags, valve bags and FFS-tubular bags. Also, filling stations for Big Bag production lines.

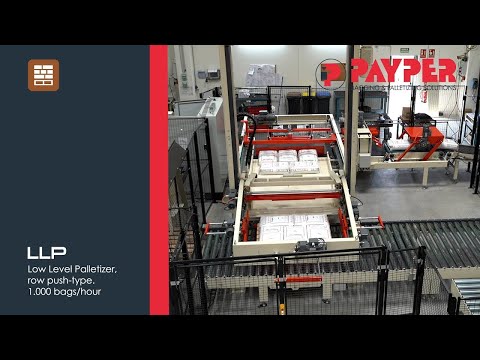

Palletizing: A wide range of robot and conventional palletizers for perfect pallet stability.

Overwrapping: End-of-line solutions for ideal finishing and protection such as wrapping machines and stretch hood machines.

PAYPER will be showcasing an FFS bagging machine from the ASSAC series at the stand. This bagging system forms, fills and seals bags from a continuous tubular reel of plastic. An efficient solution for bagging all types of bulk solids applied in the food, petrochemical, fertilizer and building industries. The ASSAC FFS bagging machine stands out for its compact and heavy-duty design with easy access for cleaning and maintenance. Among the available options are: hygienic design for the food and chemical industries and an anti-corrosion configuration for handling corrosive and abrasive products. Do not miss the opportunity to see first-hand one of the fastest bagging machines on the market with performances of up to 2,600 bags/hour.

50th anniversary

PAYPER is celebrating an important milestone in its history in 2023, its 50th anniversary.

"We are very proud of what we have achieved since we designed our first weighing system for the fertilizer industry in 1973. Today, we are recognized worldwide as one of the market leaders in packaging for bulk solids. This has only been possible as a result of the close collaboration with our worldwide team, our long-term partners and our customers which has taken us to where we are today."

Josep Mª Godia, Managing Director at PAYPER.

About PAYPER

PAYPER's headquarters was established near Barcelona, Spain, in 1973. PAYPER designs and manufactures next-generation packaging lines for bulk solids.

Customers in more than 75 different countries have chosen PAYPER as their supplier for over 4,000 projects. With 50 years on the market, it has gained extensive knowledge in numerous sectors, from the agro-food industry to the chemical and animal feed industries.

A global team of +140 highly skilled professionals provide rapid assistance throughout the product's life cycle. An efficient worldwide sales and service organization is composed of 8 subsidiaries and an extensive network of agents, ready to answer all of the customer's questions.

Press contact: Noèlia Sans - Marketing Director

Source: PAYPER