ACA, one of Argentina's main Pet food Manufacturers, decided to install new technology in their production line, as the old manual bagging system had become a bottleneck in the production line.

The company has a wide variety of extruded products with kibble sizes ranging from 2.0 mm diameter up to 16.0 mm diameter x 26 mm long, with an ethereal extract from 4.0% up to 30.0%. The bag-types are numerous as well: Open mouth paper bags and open mouth plastic bags with or without micro-perforation, with 4 seams, pillow type or laminated with metal.

The production rate of the new system should be capable of reaching 1.000 bags of 15 kg per hour. Further, it should be easy to switch between different bag sizes, from 8 to 30 kg and between different closure systems such as heat sealing, stitching and sew-through tape closure.

ACA investigated the market and visited different installations and finally decided on PAYPER for several reasons: Precise, well-functioning, and accurate machines that would fulfill future needs. PAYPER has representation in Argentina and technical service in Brazil. Together ACA and PAYPER designed the new end-of-line solution, assuring that all the demands were taken into consideration.

Requirements to the new End of Line solution:

- Precision and accuracy

- The capacity of 1.000 bags/h

- Ability to work with a variety of kibbles

- Must handle different bag materials and sizes

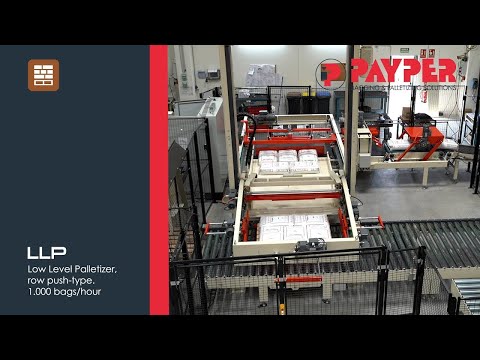

The system comprises a CSA-105 open-mouth bagging machine and a TOPLOAD palletizer.

Mr. Roberto Chunco, Head of ACA's Feed Plant in front of the high capacity automatic palletizier

'The commissioning of the installation was handled in a very professional way with thorough training of the operators. Whenever we have needed PAYPER`s After Sales Service the response has been optimal.

Since the installation in May 2017, the bagging line has proved its worth. The goal of manufacturing has been fulfilled, we have obtained the expected savings, and the presentation and the finishing of the bag are of top-quality, ready for retail. ' Mr. Roberto Chunco, Head of the Feed Plant.

'The replacement, in addition to automating allowed us significant cost savings and improvements in the final presentations of our products.' Mr Walter Brignoli, General Manager of the Feed Factory.

Marketplace

'One of the greatest satisfactions is the precision of the weighing and dosing system and the speed with which it is done' Mr José Sejas, End of Line Coordinator, Responsible for operation and maintenance.

by Bulk Inside

You could be interested: Reliable packaging & palletizing of bulk materials with STATEC BINDER machines

About company

About company

Next-Generation Bagging Lines for Pet Food

PAYPER, a Spanish company founded in 1973, specializes in designing and manufacturing machinery for dosing, weighing, bagging, palletizing, and overwrapping solutions. For more than 50 years, we have developed unique features for pet food bagging, such as air extraction from the bag to extend product shelf life or the patented technology for levelling the top of the bag to ensure a flawless closure.

PET FOOD industry customers in Latin America, have trusted us with more than 500 projects installed using PAYPER technology. From our subsidiaries in Mexico and Brazil, we offer a comprehensive service covering all the steps from the sales phase to after-sales and spare parts supply, guaranteeing close attention throughout the process.

With 8 subsidiaries and representation worldwide, our local sales and service organizations are at your disposal to answer any questions and offer you the solution that best suits your specific needs.

Contact us today to learn more about how PAYPER can help you improve your pet food bagging and palletizing operations.

Marketplace