PAYPER has recently launched a new FFS bagging machine capable of filling up to 2,600 bags/hour.

This bag filler, which is now the highest performing member of the FFS ASSAC-family, is called U20. It handles bags from 5 to 50 kg and works with tubular PE or Aluminium roll film with PE laminate and is especially suitable for bulk solids in granules.

The ASSAC-U20 is specially designed for free flowing products such as plastic pellets, fertilizer prills, etc. Common demands when bagging this kind of products are output capacity, precision and reliability and the U20 meets all three.

Five decades of experience and collaboration with the industry make PAYPER a trustworthy partner. Any new project is developed in close cooperation with the client and is tailor-made to suit each individual need.

The ASSAC U20 is a flexible bagging solution that can be adapted to different requirements by adding modules such as Automatic roll film change; ATEX certification; Anti-corrosion kit; Cleaning system; Corner sealing system for optimal bag shape or a Movable platform. Additionally, a Metal-detector, Check-weigher or Ink-printer can be added to the line to customize the entire system for the user.

Read more HERE

ASSAC-U20. PAYPER's newest FFS bagging machine – 2,600 bags/h

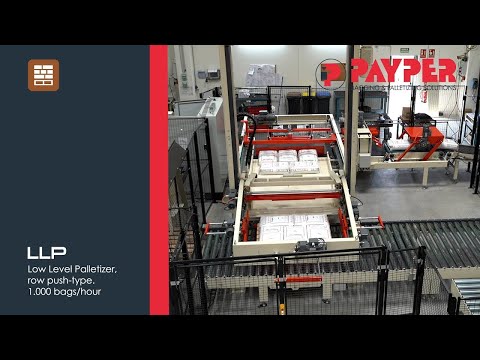

Bagging-line with PAYPER's new FFS bagger, 'ASSAC-U20' with a capacity of 2,600 bags/h. Features automatic roll film changer, metal detector and check weigher.

Automatic film roll changer fitted to PAYPER's new FFS bagging machine 'ASSAC-U20'.

PAYPER's high-speed FFS Bagging System, 'ASSAC-U20' with automatic film roll changer.

Fuente: Payper

You could be interested: Reliable packaging & palletizing of bulk materials with STATEC BINDER machines

About company

About company

Next-Generation Bagging Lines for Pet Food

PAYPER, a Spanish company founded in 1973, specializes in designing and manufacturing machinery for dosing, weighing, bagging, palletizing, and overwrapping solutions. For more than 50 years, we have developed unique features for pet food bagging, such as air extraction from the bag to extend product shelf life or the patented technology for levelling the top of the bag to ensure a flawless closure.

PET FOOD industry customers in Latin America, have trusted us with more than 500 projects installed using PAYPER technology. From our subsidiaries in Mexico and Brazil, we offer a comprehensive service covering all the steps from the sales phase to after-sales and spare parts supply, guaranteeing close attention throughout the process.

With 8 subsidiaries and representation worldwide, our local sales and service organizations are at your disposal to answer any questions and offer you the solution that best suits your specific needs.

Contact us today to learn more about how PAYPER can help you improve your pet food bagging and palletizing operations.

Marketplace