Fibers as natural and renewable plant-based materials are ecological products at their best. Because of their multifunctional properties and compatibility with nearly all other substances, fibers provide solutions for many everyday products.

The selection of the right raw material and the mechanical manufacturing process is of paramount importance, as this allows the particle size and structure to be tailored, and the properties of the fibers depend, to a large extent, on these parameters.

Through a finely tuned interaction of suitable milling technology and fractionation, optimized products can be manufactured.

ADVANCED MILLING TECHNOLOGY

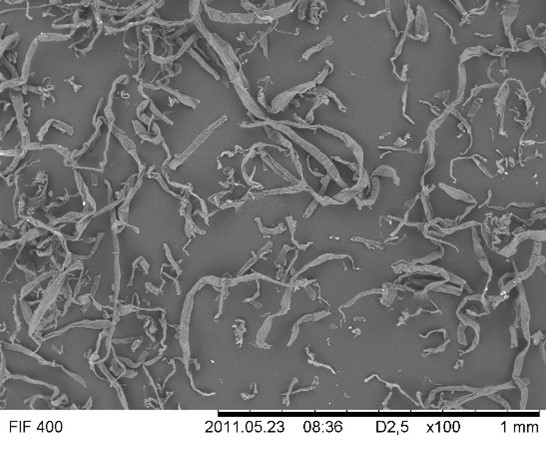

An impact mill acts on a fiber material with high shear forces. This results in strong fibrillation of the material, resulting predominantly in long, thin fibers (picture 1). In turn, these are characterized by a high binding capacity for liquids, be they water, oil, or others.

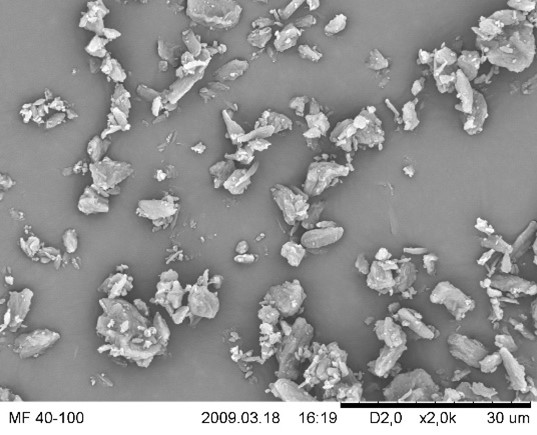

In contrast, a cutting mill mainly shortens the fiber length but is not able to split fiber bundles into individual fibers very well. Therefore, this grinding system mainly produces shorter particles with a less pronounced fiber structure (Picture 2). These particles are less effective but have a better flow, dosing, and mixing ability.

Picture 1: Long Fiber

Picture 2: Short Fiber

Other so-called 'rotor-stator systems,' which allow a very small grinding gap, are predestined for fine powder production. Although these powders do not have high functionality, they can be used in higher concentrations and can be easily and homogeneously incorporated into a wide variety of formulations. They also have good sensory properties.

APPLIED KNOWLEDGE

Having the possibility to understand how a structure or matrix of the fiber after a dedicated processing upgrade looks like is an innovative competitive advantage. Structural differences of various fibers can help to indicate certain functional properties, which are sometimes known in the industry but more often not known or not deep enough explored. This is the moment where scientific transparency meets technical application, researching the functional benefit of a new potential product in a real application like in main meals or snacks.

Marketplace

For that, JRS has set up a pilot facility in 2017 where exactly this kind of internal research is happening. Only after enough internal trials and critical analysis, the products are manufactured on a larger scale to run first trials with dedicated customers. By doing that, it is possible to develop real innovative product concepts, which are new to the market before they become standard across the pet food world.

Globally, there are thousands of innovation pipelines and marketing concepts creating a high demand for new innovative solutions. Having the right knowledge and products in place is key to being a constant part of new product developments and strategic partnerships. However, even in daily production, there are challenges where fiber can help to have a more efficient production. Some of them have the capability to generate a network, helping to keep the shape of a product intact or keeping a gravy clear during sterilization. Others can avoid syneresis in raw meat food or alternatively in all meat sausages, ensuring water excess can be held over shelf life. There are many more examples of what fiber can deliver beyond the nutritional benefit for pets.

Fibers designed by nature in combination with research & development plus technical application knowledge are the future road for many new ideas around the globe beyond nutrition.

By: JRS

Source: All Pet Food Magazine

You could be interested: Manufacturers need partners who support them in understanding the Pet Food ecosystem

About company

About company

We are a manufacturer, a problem solver, and a reliable technology/system partner for a wide range of industries. As an owner-managed family business, we are strongly rooted in our southern German region since 1878, and as a corporate group, we are now globally active, with around 4,000 employees in more than 90 locations worldwide.

A spirit of inventiveness, courage and close customer relationships has shaped what started as a classic oil and grain mill into a global market and knowledge leader in the segment of sustainable, functional Plant Fiber Technology.

At JRS, we have been making high-quality fiber ingredients for pets for more than 60 years. Today, we are a global expert in animal nutrition solution that are natural, healthy, and sustainable. Our long history producing high-quality and nutritious fiber ingredients has provided an edge in producing premium natural ingredients that pet food manufacturers can trust. The entire process from harvest, storage to the final production is done under controlled conditions in order to guarantee a complete product integrity and traceability.

JRS Petfood offers a wide range of choices for all pet food categories with benefits through all stages of our pets’ life as well as during the pet food production.

Scientifically proven ingredients and an experienced team help you analyze together the problems and develop fiber solutions.

Ingredients with added value to our pets and pet food producers.

Your all-in-one partner!

Noticias de la empresa

30/06/2023