Swiss technology group Bühler has acquired innovative puffing technology from CEREX for food, petfood, and feed applications. CEREX, a Swiss manufacturer of machines for food, feed, and non-food applications, originally developed this technology. Bühler explained that this strategic acquisition not only broadens its product offerings, providing enhanced solutions to address the growing demand for healthier and more diverse food options, but leverages the company's full potential to benefit the customer. The technology is versatile and, therefore, applicable to a broad range of products – snacks, ready-to-eat breakfast cereals, confectionery, bakery items, and dairy products.

'The puffing process is a game-changer in how we approach cereal and snack production, offering a broad range of recipe possibilities, including coatings and fillers across many product categories,' said Christoph Vogel, Head of Business Unit Human Nutrition at Bühler. 'The integration of this technology into Bühler's portfolio strengthens our ability to meet the evolving needs of our customers and fosters continued innovation in recipe development.'

Christoph Vogel

The demand for snacks like bars, extruded snacks, nuts, seeds, popcorn, and plant-based alternatives such as puffed oats – particularly among the working population and younger generations – has increased in recent years. The global ready-to-eat snack market size is expected to expand at a compound annual growth rate (CAGR) of 9.7% from 2024 to 2031. Puffing technology can support customers in quickly adapting to these emerging consumer trends, Bühler pointed out.

At a time when cocoa prices are high, the company expressed that the puffing technology also enhances production efficiency by increasing volume and weight, reducing sugar content, and cutting production costs. It therefore supports customers in finding new ways to optimize their processes and maintain profitability, which is crucial for business success.

Puffing is a hydrothermal process that uses heat and pressure to significantly expand the volume of raw materials. The process requires the material to contain 10-14% water and 65-75% starch, with protein and fat levels also affecting the outcome. Puffed products offer several advantages. Their increased volume and porosity make them lighter and crispier – a highly desirable quality for snacks and cereals. The puffing process also enhances digestibility by breaking down starches and improves shelf life by reducing moisture content and preventing spoilage. It also boosts nutritional potential as the product can easily be enriched with vitamins, minerals, or proteins.

Marketplace

Puffed products are considered healthy as they contain no added ingredients – just a single, natural component – and are available as white-label options. This technology can be used in a variety of products. In breakfast cereals, grains like rice, corn, wheat, or quinoa are puffed to create expanded, crunchy textures that are perfect for morning meals. In cereal bars, puffed grains add texture, visual appeal, and a distinctive crunch. The grains are either mixed with melted chocolate or layered on top, depending on the desired structure of the final product, providing a balance of crunch and lightness. Puffing technology is also used in dairy products, such as yogurt and ice cream, where puffed grains like quinoa, rice, or buckwheat serve as crunchy toppings or mix-ins to enhance the eating experience and nutritional value.

MAXIMUM YIELD, MORE ENERGY EFFICIENCY

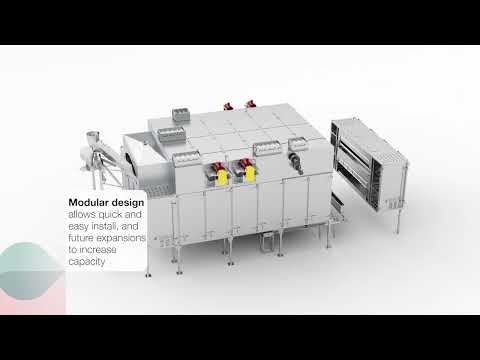

The new acquisition will not only add value to Bühler's offerings but also contribute to the production efficiency and sustainability of customers' plants, the company emphasized. Bühler's Cerex puffing technology significantly enhances grain processing by achieving maximum yields of over 95%, reducing waste while ensuring uniform puffing across all grains. The system operates with remarkable energy efficiency, consuming 50% less energy compared to similar systems – it utilizes 60 kilowatt-hours (kWh) per 100 kilograms (kg) of product as opposed to 120 kWh. Additionally, it ensures a stable and industrial-grade puffing process compliant with the strictest food safety regulations.

Puffing system reactors: it eliminates the disruptive 'gunshot noise' typical of older systems.

In April 2025, Bühler will open an Application & Training Center at its headquarters in Uzwil, Switzerland, focused on the puffing technology. At the Center, customers will be able to test new product recipes with ingredients such as pulses and develop new processes applying this technology.

'By incorporating advanced puffing technology, we are confirming our commitment to innovation, addressing both current market demands and anticipating future consumer trends,' expressed Vogel. 'Now, we are ready to discuss with our customers the exceptional opportunities for integrating this solution into their plants.'

According to the announcement, the collaboration with CEREX on puffing technology strengthens Bühler's ability to provide innovative solutions in the cereal and snacks market while not impacting CEREX's other services, machine portfolio, or operations. Puffing technology for non-food and non-feed applications remains in the exclusive purview of CEREX.

Source: Feed Additive

You could be interested: JBT Marel to Host Pet Food Open Day & Seminar in Belgium

About company

About company

Who are we?

We are a Swiss family company with more than 150 years in the market, present in more than 140 countries, 30 manufacturing sites, and 100 service stations. Allowing us to be a leader in the supply of technologies and solutions for the transformation of grain into flour and food, as well as in the production of pasta and chocolate. We also provide the solution to produce feed, petfood and aquafeed. Our portfolio also includes die-casting, wet milling, and surface coating processes.

Bühler began operations in Mexico in 1959, and currently has headquarters and a service station in the city of Toluca, from which it serves the region of Mexico, Central America, and Cuba, with the sale of equipment and spare parts, engineering, automation, technological consulting, roll reconditioning among others.

How can we support the pet food, fish, and shrimp food industry?

Bühler is capable of supplying the complete solution for feed, petfood and aquafeed, based on the following pillars: food safety, efficiency, and sustainability. Therefore, we can provide from plant design, pre-engineering, installation, to automation services, plant assessments and training, all based on personalized attention from sales, technology, and customer service, seeking to develop our customer´s success with long-term relationships.

Our process solutions range from the grain receiving, cleaning and handling systems, storage, ingredient dosing, mixing, fine and wide grinding, extrusion (single or double shaft extruders), pelleting, drying, coating, and cooling. Enabling the production of wide range of products: sizes, colors, textures, and ingredients.

We invite you to learn about the success stories of our customers around the world, our solutions and, above all, to schedule an appointment with our industry specialists, who look forward to serving you.

Noticias de la empresa

06/12/2023

Agroloop commissions Bühler to provide proven insect-rearing tech for animal feed

22/09/2023