Jorge, could you tell us about your professional background and the focus of your current role as Sales Director at Bühler?

My journey at Bühler began in 2000, 25 years ago, as a Project Engineer. Ten years later, I took on the role of Sales Manager for several Bühler divisions after spending three years training at the company's headquarters in Switzerland. Starting in 2010, I became Sales Director for the Animal and Human Nutrition Division for Mexico and Central America. I am a Mechanical Engineer with various training courses in processes at our headquarters in human and animal nutrition. I graduated from the SFT (Swiss Institute of Feed Technology), and I hold a degree in Business Management from IPADE and EGADE Monterrey.

Our main focus is to position ourselves as market leaders by offering the service and technological support customers expect to achieve their strategic plans, which are increasingly demanding and competitive.

What is the scope of Bühler technologies, and how do they optimize the lives and processes of those who use them?

As a global leader in technology development for the food and mobility industries, Bühler is present in the daily lives of millions of people, from the moment they wake up to when they go to bed, helping them meet their basic needs. Our technologies are present in their smartphones, solar panels, banknotes, lipsticks, the food they eat, and the vehicles they drive. We strive to innovate for a better world with a special focus on healthy, safe, and sustainable solutions.

How do your products and solutions contribute to the pet food industry?

The pet food industry is so fundamental that Bühler has integrated it under the Human Consumption Division. This ensures that, with our advanced technologies and automation, our customers obtain precise traceability and control of the entire extrusion process, both single and twin shafts. The result is a reliable, high-nutritional-value, healthy, and easily digestible food for pets.

Do you currently have any pet food projects in development or soon to be launched you can share with us?

Bühler is a company that invests up to 5% of its turnover in new technologies each year, and the Pet Division is no exception. Some of these developments are already underway in projects such as:

Marketplace

Kibble humidity measurement and control at the dryer exit, as it is crucial because this is where you can make or lose money. That's why Bühler launched our "DryingPro," which helps measure and control humidity in real-time to increase drying process performance and profitability.

Kibble production ingredient mix accuracy and precision: This is optimized with various weighing equipment at different points in the process, from the extruder inlet to before packaging, thereby reducing waste within the process.

The particle size spectrum after milling, which is vitally important for achieving good mix homogeneity, as well as for the texture and cooking of the ingredients during the extrusion process. To achieve this, Bühler has a technology that controls this particle size, achieving improved kibble quality in every sense.

What are the distinguishing features of your Granulex model and its applications?

Our Granulex Series 5 hammer mill can provide energy savings capacity increases of up to 10% and time savings of up to 50% when changing hammers and screens. It also features an explosion-proof design to improve production safety.

The Granulex Series 5 mill is used by demanding industries that require grinding raw materials from very coarse to fine for feed or grains, such as the pet food industry, malt and beer, and general pre-milling.

And what can you tell us about the Imdher-Bühler alliance? How do you think it benefits the industry?

It is a strategic plan that has revolutionized the pet and feed industry, offering turnkey projects from a single supplier, primarily for Mexico. We have managed to integrate the experience of Imdher, a 100% Mexican company with more than 40 years in the market, with that of Bühler, with more than 170 years of creating cutting-edge technology for a better world.

Speaking of the market, how do you see the pet food industry in Mexico and Central America? At what stage do you think it is now?

Mexico, one of the largest markets in the world after the United States and Brazil, is gradually becoming saturated with a measured growth of approximately 4% annually, after growing at a rate of over 12% for the last 10 years. Differentiation will begin with high-quality products, as basic products will face intense competition, and a price war will start. This is where cutting-edge technology will play an important role in receiving byproducts from other industries and replacing some raw materials that will be expensive or difficult to obtain.

The rest of Central America is a smaller but rapidly growing market, which should be taken advantage of by local manufacturers or large Mexican producers who can export kibble while maintaining tariffs the Central American market faces on products from outside these countries.

In your view and experience, where is the pet food industry heading, technologically speaking? How do you think artificial intelligence is impacting it?

The pet food market is becoming more humanized due to the close relationship between pets and humans. Therefore, the way pet food is produced must be stricter and comply with certain regulations that, currently, are not applied or considered. Technology will play a very important role every day, together with raw materials, which are increasingly difficult to process. This is where twin-shaft extruders and more efficient packaging systems must be considered given their broad production flexibility.

AI is already present in production processes, healthcare, and disease prevention. Regarding food production, AI is becoming increasingly necessary through automation. It can fix process errors, allowing machines to adjust themselves to improve efficiency, performance, and traceability, and control human error, not to mention that manpower in Mexico and Central America is increasingly scarce. Today, we must consider new production plans and the integration of our new generations so that they adapt to each market's needs.

What place does sustainability have in the company's vision? How do Bühler's innovative solutions face climate change?

For Bühler, sustainability is essential for our regulatory framework, balancing humanity, nature, and the economy and involving our own company, suppliers, and customers. Regarding nature (the environment), we created a plan that began five years ago in which we committed to reducing waste, water, and energy use in our customers' value chain by 50% by 2025. Additionally, we have developed a path to achieve a 60% reduction in greenhouse gas emissions across all our operations by 2030.

Thank you, Jorge, for sharing your knowledge and Bühler updates with the All Pet Food community!

By Jorge Guzmán

Source: All Pet Food Magazine

You could be interested: The interview: Maximilian Furley

About company

About company

Who are we?

We are a Swiss family company with more than 150 years in the market, present in more than 140 countries, 30 manufacturing sites, and 100 service stations. Allowing us to be a leader in the supply of technologies and solutions for the transformation of grain into flour and food, as well as in the production of pasta and chocolate. We also provide the solution to produce feed, petfood and aquafeed. Our portfolio also includes die-casting, wet milling, and surface coating processes.

Bühler began operations in Mexico in 1959, and currently has headquarters and a service station in the city of Toluca, from which it serves the region of Mexico, Central America, and Cuba, with the sale of equipment and spare parts, engineering, automation, technological consulting, roll reconditioning among others.

How can we support the pet food, fish, and shrimp food industry?

Bühler is capable of supplying the complete solution for feed, petfood and aquafeed, based on the following pillars: food safety, efficiency, and sustainability. Therefore, we can provide from plant design, pre-engineering, installation, to automation services, plant assessments and training, all based on personalized attention from sales, technology, and customer service, seeking to develop our customer´s success with long-term relationships.

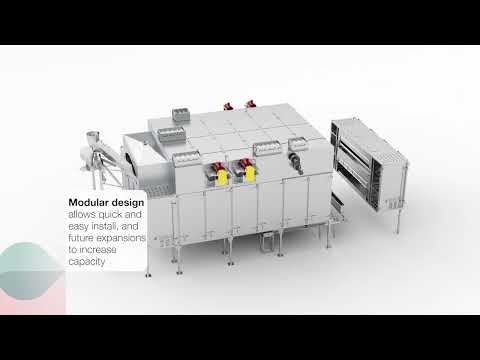

Our process solutions range from the grain receiving, cleaning and handling systems, storage, ingredient dosing, mixing, fine and wide grinding, extrusion (single or double shaft extruders), pelleting, drying, coating, and cooling. Enabling the production of wide range of products: sizes, colors, textures, and ingredients.

We invite you to learn about the success stories of our customers around the world, our solutions and, above all, to schedule an appointment with our industry specialists, who look forward to serving you.