From the point of view of a pet food manufacturer, the answer would again be everyone. But I want to invite you to reflect for a moment on all the ingredients that make up a balanced meal. It is critical that pet food producers and pet owners maintain confidence in the quality and food safety of all ingredients, as well as traditional and innovative, used in pet food, treats, and snacks.

Let's take the pet owner's ingredient of choice: protein. In fact, protein is a nutrient whose source (which can be of animal or vegetable origin) is responsible for providing the protein in the food formula, so it must comply with quality, correct composition, food safety, and physical characteristics, among others.

We can continue going through every one of the ingredients we use in the food formulas but I would like to dwell on an ingredient of the balanced food formula that is made up of multiple elements inside: the vitamin premix (13 vitamins) and trace minerals (6 minerals). This ingredient is a homogeneous mixture of one or more micro-ingredients, designed to allow uniform dispersion of multiple nutrients within a pet food that must be present at milligram or microgram levels.

Although premix is typically used at low inclusion levels, its role in the feed requires us to pay close attention to this ingredient, as 1 ton of "unsafe" premix could cause illness in many pets and may require tons of pet food to be eliminated from stores and pet houses (figure 1). Recalls cause distress to pet owners, have an adverse economic effect on pet food manufacturers, and result in a loss of confidence in the pet food supply chain as a whole.

Figure 1. The example given is based on 1 tonne of premix used in a 5kg inclusion per tonne of dog food. The dog food is packaged in 10kg bags and sold to 20,000 owners, each with 1 dog.

It is essential to use a safe premix, which guarantees risk control at all stages of the food chain, from the selection and approval of ingredients to the packaging of the finished product. Control loss at any of these steps could result in the supply of "unsafe" premixes.

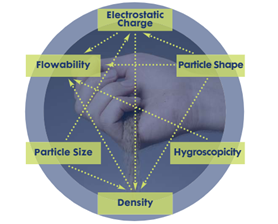

A safe premix starts with design, the core step in achieving a mix with a homogeneous and uniform dispersion of each ingredient to ensure that the pet food provides a good level of nutrition. The design of a premix considers certain ingredient characteristics and interactions that influence nutrient segregation, stability, and biological response (Figure 2).

Figure 2. Interactions between ingredients' characteristics.

A premix is made up of different microingredients with different physical and chemical characteristics that will determine the good performance of the premix in the final feed. Here, the complexity and the importance of knowing each component begins. Within the physical characteristics, there is particle size. Smaller particle size is beneficial if the active ingredient has a low inclusion level per tonne of feed. As the particle size decreases, the number of particles increases, thus improving dispersion. We would then think of looking to work with ingredients with small particles, but as the particle size decreases, the electrostatic charge also increases.

A high electrostatic charge causes particles to be attracted to metal surfaces, such as mixing and conveying equipment. In addition to particle size, there is the particle's shape, which affects the density of an ingredient and, consequently, that of the premix. And density influences the packaging and flow characteristics of the premix. Achieving good flowability is important to ensure that materials are accurately weighed, added, and dispersed within the premix. Finally, the smaller particles have the capacity to absorb more moisture; they are more hygroscopic because they have a larger contact area, and there is more interaction between the particles. Hygroscopic ingredients can cause the premix to cake up or change color, indicating that a chemical reaction has occurred.

After the design, the manufacturing process must be accurate and consistent to meet legal, quality, and safety requirements for the premix. Its manufacturer must subject all ingredients to a risk assessment process that identifies food safety and quality hazards associated with the ingredients, including the source, manufacturing process, and supply chain. The mixing equipment must be in optimal conditions and within a maintenance and cleaning program to ensure the mixing of the components and preserve the integrity, quality, stability, and nutritional value of each microingredient. Finally, before shipping a premix, it must be checked and ensured that the quality of the product meets legal requirements and customer specifications and that all critical control points and operating procedures are completed.

To sum up, we can affirm that all the ingredients that make up a balanced pet food are important and must be subject to strict quality control and assurance. There is a very particular ingredient, the premix of vitamins and trace minerals, which is responsible for providing many nutrients to the final diet. These nutrients go in very small quantities in the feed, in the order of ppm, so having a safe premix is essential. Safe premix is a great responsibility and must have all the control processes in the ingredients and in the manufacturing process.

Fuente: Armando Enriquez de la Fuente

You could be interested: Additives in pet food

About author

Armando Enriquez de la Fuente BlanquetArmando Enríquez is from Mexico and, currently, works at Novus International as a Regional Country Manager, Mexico. Before, he worked at Trouw Nutrition Mexico as Feed Additives & Key Accounts Manager; he is also part of the company’s Global Companion Animal Community. He worked for DSM Nutritional Products in various positions: as a Marketing Manager in Pet Nutrition in Latin America, Vitamins Technical Manager in Latin America, Food Chain Project Manager and Commercial Manager in Mexico. He also worked at Roche Products as a Pets Project Manager, Ruminants Project Manager and Commercial Manager. He publishes editorials in specialized magazines in the Petfood industry and has lectured at the Andean Pet Forum in Colombia and at the Pet Forum, Mexico. He is a Veterinary Zootechnician from the National Autonomous University of Mexico and has a master's degree in Business Administration from the ITESO University.