Swiss Bühler Group and Premier Tech from Canada, announced the formation of a strategic cooperation for industrial flexible packaging solutions.

Both companies agreed to build a design and manufacturing center in China. 'Combining the portfolio and expertise of Premier Tech and Bühler will enable future packaging solutions which are significantly more efficient, accurate and food safe by using automation technologies', says Johannes Wick, CEO of Bühler's Grains & Food business.

'The two companies are complementing each other in a perfect way with Bühler's strong footprint and market position in China and Premier Tech's recognized know-how in the field of automated packaging technologies,' says André Noreau, CEO of Premier Tech's Systems and Automation business.

In grain processing, packaging is the last step before transporting flour to bakeries and other food processors, rice to distributors or pellets to farms. In many cases – especially in developing countries – the bagging operation is still done manually. This is not only inefficient, costly, and slow, but also implies a certain variation of weight and therefore a higher give away of the packaged goods. Palletizing solutions are increasingly important to allow for efficient warehousing solutions.

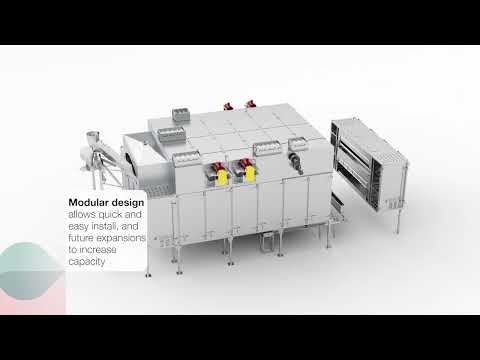

The market and technology leading companies – Premier Tech in packaging and Bühler in grain and food processing – are now establishing this strategic cooperation to meet these market demands and create new cost-effective packaging solutions. Bühler brings its know-how of high-quality manufacturing and supply chain management in China as well as its digital solutions, whereas Premier Tech contributes with its superior packaging expertise and technological leadership in this field. In bringing these competencies together, the strategic cooperation will develop automated, food safe and accurate bagging and palletizing solutions.

The strategic cooperation will allow Bühler to provide better turnkey projects with competitive packaging solutions from China while continuing to deliver high-end products such as Bühler's bagging station Maia from its own manufacturing network in Europe.

At the same time, Bühler will continue to design and market their proven weighing portfolio (since scales such as Tubex are not part of the agreement) and further improve its digital services allowing for full transparency and traceablity. Premier Tech will gain better access to the Chinese market by using the cost-effective and modern packaging solutions arising from the strategic cooperation, or by combining them to its internationally renowned CHRONOS technology portfolio in weighing, bagging, and palletizing.

Marketplace

This strategic cooperation is planned to result in a joint venture for design and manufacturing during 2020, with Bühler focusing on sales of turnkey plants around the world, and Premier Tech on packaging systems in China. Both companies will continue to sell their products through their existing channels.

About Premier Tech

Making a difference, this is what we are all about at Premier Tech. One team driven by the shared passion to deliver solutions that we better the lives of people, businesses and communities. At Premier Tech, People and Technologies connect in lasting, transformative ways, giving life to products and services that help feed, protect and improve our world. We are committed to creating sustainable solutions that help bring beautiful gardens to life, increase crop yields, improve the efficiency of manufacturing facilities, treat and recycle water, and much more as we keep innovating.

For more than 95 years, Premier Tech has been growing internationally, driven by the collective power of its 4 500 team members in 27 countries. Backed by a quarter-century-long track record of solid growth, Premier Tech today records sales of nearly CAD 1.0 billion.

About Bühler

Billions of people come into contact with Bühler technologies to cover their basic needs for food and mobility every day. Two billion people each day enjoy foods produced on Bühler equipment; and one billion people travel in vehicles manufactured with parts produced with our machinery.

Countless people wear eye glasses, use smart phones, and read newspapers and magazines, all of which depend on Bühler process technologies and solutions. Having this global relevance, we are in a unique position to turn today's global challenges into sustainable business. We want every human being to have access to healthy food. We want to do our part to protect the climate with energy-efficient cars, buildings, and machinery.

Our motto is creating 'innovations for a better world.' Bühler invests up to 5% of turnover into research and development. In 2018, over 13,000 employees generated a turnover of CHF 3.3 billion. As a Swiss family-owned company, Bühler is active in 140 countries around the world and operates a global network of 30 production sites.

by All Extruded

You could be interested: Reliable packaging & palletizing of bulk materials with STATEC BINDER machines

About company

About company

Who are we?

We are a Swiss family company with more than 150 years in the market, present in more than 140 countries, 30 manufacturing sites, and 100 service stations. Allowing us to be a leader in the supply of technologies and solutions for the transformation of grain into flour and food, as well as in the production of pasta and chocolate. We also provide the solution to produce feed, petfood and aquafeed. Our portfolio also includes die-casting, wet milling, and surface coating processes.

Bühler began operations in Mexico in 1959, and currently has headquarters and a service station in the city of Toluca, from which it serves the region of Mexico, Central America, and Cuba, with the sale of equipment and spare parts, engineering, automation, technological consulting, roll reconditioning among others.

How can we support the pet food, fish, and shrimp food industry?

Bühler is capable of supplying the complete solution for feed, petfood and aquafeed, based on the following pillars: food safety, efficiency, and sustainability. Therefore, we can provide from plant design, pre-engineering, installation, to automation services, plant assessments and training, all based on personalized attention from sales, technology, and customer service, seeking to develop our customer´s success with long-term relationships.

Our process solutions range from the grain receiving, cleaning and handling systems, storage, ingredient dosing, mixing, fine and wide grinding, extrusion (single or double shaft extruders), pelleting, drying, coating, and cooling. Enabling the production of wide range of products: sizes, colors, textures, and ingredients.

We invite you to learn about the success stories of our customers around the world, our solutions and, above all, to schedule an appointment with our industry specialists, who look forward to serving you.

Noticias de la empresa

03/09/2024

Exciting News: Big Idea Ventures, in partnership with Mars Petcare and Bühler Group, is launching the Next Generation Pet Food Program

06/12/2023

Agroloop commissions Bühler to provide proven insect-rearing tech for animal feed

22/09/2023