Waste, defects and rework: It is usually a 'nightmare' in food processing, here we suggest how to minimize and control it.

When we talk to our customers about their most important problems in the production processes in food processing, almost all of them mention one or more: waste, defects and rework. InfinityQS® quality management software is designed to help manufacturers know exactly what to expect… so there are no unpleasant surprises.

It's so true that waste, defects, and rework are the nightmare of today's manufacturing. Because if you don't control your processes, these problems will cost you money and headaches. Often times, despite your best efforts, poor quality products eventually find their way into the hands of your customers.

With so many competitors in every market segment, one of the biggest differentiators is quality. In any organization, you must implement quality in a standardized way to ensure that metrics are met, and objectives are achieved. Simply put, it´s essential to consistently maintain the highest quality and deliver the highest quality levels 24 hours a day, 7 days a week.

That's why InfinityQS quality management software systems are vital to today's manufacturers. The stakes are high, but the cost of the solution for scraps, defects, and rework doesn't have to be.

QUALITY as a Priority!

InfinityQS´ COO, Doug Fair, says on his blog: "...Are Quality Control Methods 'Mission Critical at Your Organization?" that: 'companies that make quality a priority in their manufacturing create a huge market advantage, have reduced operating costs, allowing them to lower prices to be more competitive or keep prices unchanged and earn additional profits. When quality is a mission critical, companies experience fewer failures, fewer warranty claims, greater customer loyalty ... and higher sales...'

When companies make quality a priority, they can easily reduce waste, defects, reprocesses.

In essence, this is all about the ability to make quality work for you. By using statistical process control, through a quality management software system (as offered by InfinityQS and its Partnet, Clivio Solutions), you have the best chance of keeping at bay the demons of manufacturing.

Control Processes

A quality management solution can reduce waste by helping your operations team detect critical out-of-spec dimensions. The earlier you detect these problems, the less wasted materials or recalled products you will have to deal with. InfinityQS quality management solutions provide the tools you need to detect process problems quickly.

Let's face it: you can't stop waste if you can't find it. Too many companies use guesswork to figure out why the product is not up to scratch. But with the InfinityQS cloud-based quality management system -- the Enact® Quality Intelligence platform - which is offered and supported by Clivio Solutions, you can identify how to reduce waste in manufacturing and significantly reduce costs in all its operations.

Fighting waste is a never ending battle. Enact® gives you the power to accumulate historical and aggregated data on processes, products, lines and even sites, which in turn gives you the ability to track trends and variations that generate waste, even for processes and products that are within the limits. Specifications. As a result, InfinityQS customers have saved many millions of dollars by reducing waste.

As Steve Wise, Vice President of Statistical Methods at InfinityQS, writes in his Manufacturing Challenge blog series: "...Generally speaking, management doesn't really care about waste; what matters to them is the profit. Well, to be fair, they do care; but they don't want to deal with it if they don't have to. As long as they are making money, they simply won't have time to spend worrying about waste. And so these 'hidden factories' continue to exist... ".

The Hidden Factory

What is the "hidden factory" It consists of the "alternative solutions" that an organization creates: small one-time solutions (usually additional steps or additional parts that do not really belong in a product) which solve the problems that operators encounter with processes and lines of manufacturing.

"...But in today's - highly competitive - market - with falling profit margins and high failure price, all organizations must take a hard look at waste. They need to expose the hidden factory and take care of its processes. It is the result of improved manufacturing quality..."

Beyond inspections

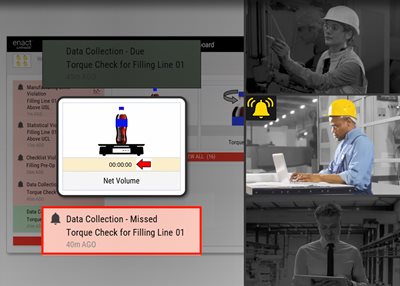

When you test quality only on the finished product or at the final production stage, you may run into staggering amounts of waste and scrap, poor quality products, or rework time. Enact® enables automatic notifications and tiered quality controls. That way, operators and quality personnel know immediately if a process, machine or product is out of specification, then they can fix the problem before it causes damage.

Enact® allows a 'big picture' view of whether processes are running smoothly or need attention. When you see a problem, it's easy to drill down into the details of real-time alerts and trade status for better troubleshooting and faster resolution.

The main purpose of inspections and samples, or sample-based inspection plans, is to capture defects before they leave the plant.

InfinityQS through Clivio Solutions allows manufacturers to look "upstream" for the root causes of these problems and detect (and eliminate) them.

Working upstream

If you can't figure out where things are going wrong, you will likely end up waiting until even more "added value", and more costs, are attached to the product. Then, just at the last minute before it is shipped to the customer, what should you do? Do you throw it away or take it out of stock. ?

On the other hand, when you do manage to catch something upstream, it's just one component you need to discard, rather than the entire batch. But you need to know what to do when you find that defect upstream.

Using statistical methods, which are the core of InfinityQS' quality management software products, will help you pinpoint where the problem is (the root cause) and help you determine what you can do about it. This is the strength of statistical process control. And this is what Clivio Solutions can help you with.

Solutions

If you can focus on uncovering root causes and eliminating source variation, you can eliminate many of the additional costs that creep into your production processes. These costs are often the result of people trying to fix something quickly or make the best of a deteriorating situation.

But the key to all of this is that your organization cannot be blind to excess waste, defects, or rework.

Rather, you must acknowledge the problems and put a quality team on the case. There is no reason to leave money on the table while ignoring or hiding problems. Don't be fooled: none of this is "the cost of doing business." It just isn't.

Businesses must recognize what their problems are, where they reside, seek smart solutions, and then the bottom line will reflect their efforts. There is nothing to fear. InfinityQS quality management software solutions are designed to lead you to quality excellence, supported by the professional and industry expertise of Clivio Solutions.

You will be surprised to know how simple and economical it is to implement InfinityQS quality management software with the support of Clivio Solutions. We await your inquiry.

For more information you can contact: Engineer Francisco Pantoni

Source: Clivio Solutions

You could be interested: RBS Baked Pet Food Systems: Optimized, Automated Solutions for Baked Pet Treats and Baked Kibble (Part 2)

Manufacturing Process

20/02/2025

RBS Baked Pet Food Systems: Optimized, Automated Solutions for Baked Pet Treats and Baked Kibble (Part 1)

02/10/2024