Low Angle of Repose

To start our investigation, we look at the material itself. Is it aeratable and, once aerated, does it fluidize like a liquid?

We can evaluate this by measuring the material's angle of repose. Picture a pile of material sitting on a flat surface. The angle of repose is the angle between the flat surface and one side of the pile. Higher angles of repose happen when a material is cohesive and sticks to itself. Lower angles of repose mean the material is more free-flowing and could potentially be floodable.

Low-angle-of-repose materials are more prone to flushing out of a feeder than those with higher angles of repose.

Refill Set Points

The next place to look? Refill setpoints.

When the feeder calls for a refill, the incoming material aerates the material inside of the feeder. This can fluidize this material and flush it out of the feeder. When that happens, the entire line must be paused so the feeder can be properly refilled again.

The solution? Raise the set point until there is a nice heel or head of material over the feed screw. This will protect the rest of the material inside the feeder from the charge coming in. Because it is protected, the material inside of the feeder doesn't fluidize.

In other words, you can prevent flushing of a low angle-of-repose, floodable material with more frequent, smaller refills.

Material Voids

We have looked at issues affecting low-angle-of-repose materials. However, even high-angle-of-repose materials sometimes flood out of a feeder. Two scenarios contribute to this:

- Ratholing

- Material bridges

Figure 1: Ratholing example

There is also the material bridge scenario. Like a rathole, a material bridge involves a small void. In this case, the void occurs in the shape of a small bridge over the feed screw. When this bridge collapses, the material can flush out of the feeder.

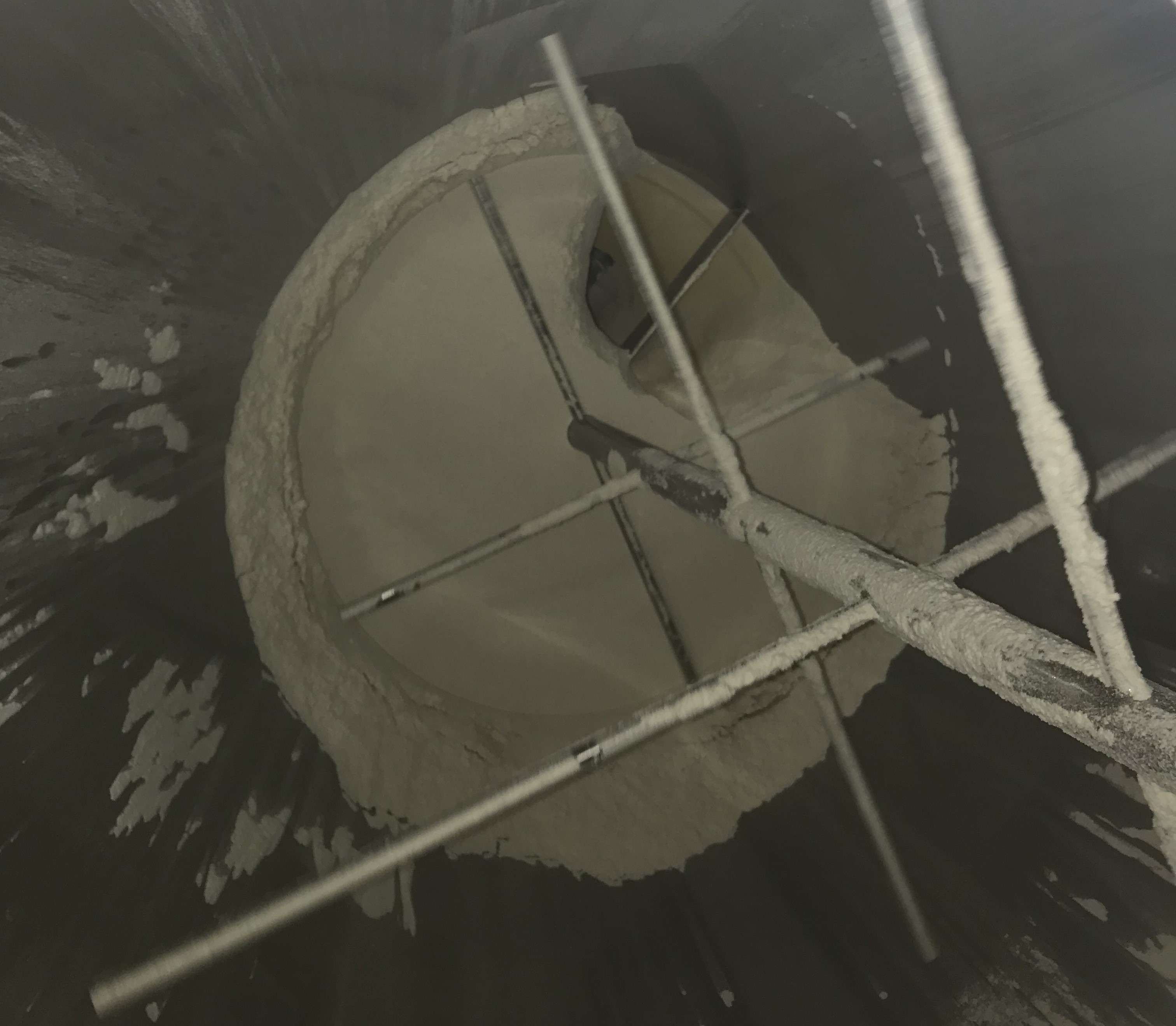

In either of these scenarios, a feeder with internal agitation may be needed to keep material from ratholing or bridging.

Figure 2: Internal feeder agitation

The next place to look is with the refill system itself: gravity, pneumatic, or vacuum.

Gravity System

In a typical gravity system of a bin with a refill valve at the bottom, a long drop to the feeder can cause the material inside the feeder to aerate and flush out. There are two ways to address this:

- Move the refill valve (butterfly valve or slide-gate valve) closer to the feeder so the material does not have as far to fall. This is the best option, but may not always be possible.

- Install a baffle inside the feeder's extension hopper. The baffle can be a piece of angle iron pointed up toward the inlet of the feeder's extension hopper. Or it can be a conical piece of material supported inside the feeder. These will baffle the impact of the material coming into the feeder. However, installing baffles can be tricky—material may hang up on them, and the hopper could eventually become blocked.

Pneumatic and Vacuum Systems

In a pneumatic or vacuum-type system, material that has been aerated before entering the feeder can also cause flushing.

The solution is to give the material enough time to de-aerate after being picked up and conveyed. A larger refill bin above the feeder will allow the material to de-aerate before it is introduced into the feeder.

Figure 3: Refill bin above a feeder

Is the material only flushing with the first refill? Filling a feeder with a floodable material for the first time can cause the material to flood out of the feeder. Three ways to prevent flooding in this situation are:

- Incorporating a center rod inside the feed screw to take up the void in the feed screw spiral or helix.

- Using a side discharge, which gives the material a wall or end cap to overcome before it is fed out.

Using a discharge plunger to stop the discharge of the feeder during the initial refill, then opening the discharge of the feeder the rest of the time. This is ideal for extremely floodable materials.

Figure 4: Helix with center rod

Clogged Filtration System

Another place we need to look at is the filtration system of the feeder. If the feeder has a blinded-up dust sock, the air inside the feeder cannot move out as new material comes in. Air will always take the path of least resistance, so if one exit is plugged (dust sock), the air will find its way out through the discharge point of the feeder—and it will bring the material with it.

Downstream Effects

Finally, what is downstream of the feeder? Are we feeding into a pressurized or vacuum-type system below the feeder? The vacuum may be strong enough to pull the material out of the feeder before the feeder has a chance to weigh it. If this is the case, investigate isolating the feeder from the downstream vacuum with a vented rotary airlock or a smaller screw conveyor.

Reach Out for Help

Hopefully, these scenarios have given you some ideas of what to look at if you experience a flushing or flooding feeder. Feel free to give an applications engineer a call to help troubleshoot your system or, better yet, have a technician come out. This small investment can prevent significant losses of revenue from downtime and product waste.

By: Todd D. Messmer - Weighing and Feeding Product Manager

Source: Schenck Process

You could be interested: RBS Baked Pet Food Systems: Optimized, Automated Solutions for Baked Pet Treats and Baked Kibble (Part 2)

Manufacturing Process

20/02/2025

RBS Baked Pet Food Systems: Optimized, Automated Solutions for Baked Pet Treats and Baked Kibble (Part 1)

02/10/2024