Bühler has launched the multifunctional single-screw extruder PolyOne for the pet food and aqua feed industry at VICTAM International 2019 trade fair.

At VICTAM International 2019 trade fair, Bühler is showcasing solutions for the entire feed value chain, with a special focus on how to use digital services to make the feed industry safer, and more profitable. LumoVision, the revolutionary data-driven maize sorting technology, finds its way into the feed processing industry. Today, Bühler has launched the multifunctional single-screw extruder PolyOne for the pet food and aqua feed industry.

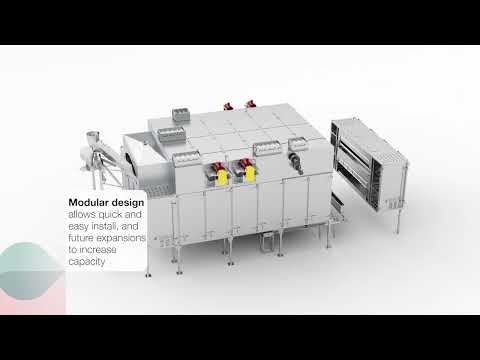

Bühler has launched its new single-screw extruder PolyOne today, designed to consistently deliver high product quality for the pet food and aqua feed industries. 'PolyOne enables our customers to maximize their productivity, and helps to prevent product recalls,' says Christoph Naef, Head of Business Unit Nutrition at Bühler Group. PolyOne meets highest food and feed safety standards thanks to its perfected hygienic design. It is a modular system so Bühler can adapt PolyOne to customers' specific needs, such as higher capacities.

Kubex T: High-capacity pellet mill with full process transparency

Kubex T provides highest process transparency thanks to an application that connects it to Bühler Insights, the pioneering cloud platform for the food and feed industry. A dashboard visualizes data for customers, making their processes transparent. This allows for seamless tracking and brings production downtimes to a minimum. Algorithms and Bühler experts help millers to optimize the mill's parameters.

With it, customers achieve higher profits and lower production costs thanks to innovations in intelligent process optimization. Kubex T is designed for high-capacity pelleting. Customers will use up to 20% less energy compared to conventional pellet mills, benefit from high production capacities of up to 80 tons per hour, and a customer-driven design, all of which are the result of extensive Bühler research and development in cooperation with leading feed millers.

Bühler LumoVision: data-driven grain sorting technology for feed and food

Marketplace

Bühler showcases its breakthrough sorting technology for the feed industry. LumoVision minimizes toxic contamination in maize and improves yield, by identifying and removing cancer-causing, aflatoxin-infected grains. It does this more accurately and at greater speed than any previous solution. Developed in partnership with Microsoft, LumoVision is a significant advance for the maize processing industry in its fight against toxic metabolites produced by fungal molds called mycotoxins, the most poisonous of which is aflatoxin.

The innovation can eliminate up to 90% of contaminated maize. 'Advances in digital technology, together with our sorting, food, and feed safety expertise, make this an unrivalled system that contributes to solving a major global security challenge,' says Matt Kelly, Managing Director of Digital Technologies at Bühler.

Aflatoxin is classified as a primary human carcinogen by the International Agency for Research on Cancer. Approximately 500 million people worldwide are at risk of exposure to it and it is estimated to cause up to 155,000 cases of liver cancer every year and contribute to stunting the growth of millions of children.

by buhlergroup.com

You could be interested: New research brief: Dental stick extrusion utilizing spray dried plasma (SDP)

About company

About company

Who are we?

We are a Swiss family company with more than 150 years in the market, present in more than 140 countries, 30 manufacturing sites, and 100 service stations. Allowing us to be a leader in the supply of technologies and solutions for the transformation of grain into flour and food, as well as in the production of pasta and chocolate. We also provide the solution to produce feed, petfood and aquafeed. Our portfolio also includes die-casting, wet milling, and surface coating processes.

Bühler began operations in Mexico in 1959, and currently has headquarters and a service station in the city of Toluca, from which it serves the region of Mexico, Central America, and Cuba, with the sale of equipment and spare parts, engineering, automation, technological consulting, roll reconditioning among others.

How can we support the pet food, fish, and shrimp food industry?

Bühler is capable of supplying the complete solution for feed, petfood and aquafeed, based on the following pillars: food safety, efficiency, and sustainability. Therefore, we can provide from plant design, pre-engineering, installation, to automation services, plant assessments and training, all based on personalized attention from sales, technology, and customer service, seeking to develop our customer´s success with long-term relationships.

Our process solutions range from the grain receiving, cleaning and handling systems, storage, ingredient dosing, mixing, fine and wide grinding, extrusion (single or double shaft extruders), pelleting, drying, coating, and cooling. Enabling the production of wide range of products: sizes, colors, textures, and ingredients.

We invite you to learn about the success stories of our customers around the world, our solutions and, above all, to schedule an appointment with our industry specialists, who look forward to serving you.

Noticias de la empresa

03/09/2024

Exciting News: Big Idea Ventures, in partnership with Mars Petcare and Bühler Group, is launching the Next Generation Pet Food Program

06/12/2023

Agroloop commissions Bühler to provide proven insect-rearing tech for animal feed

22/09/2023