Introducing EXPRO AI™: The Future of Extrusion Operations

EXPRO AI™ employs sophisticated AI predictive modeling to analyze historical and real-time process and quality data. By identifying relationships between critical data points, specifications, and operational anomalies, EXPRO AI™ delivers actionable insights that enable manufacturers to predict product quality outcomes and prescribe ideal process setpoints. The result is a significant reduction in process variability and consistently superior product quality.

Key Features and Benefits:

- Real-Time Digital Twin Dashboard: Offers real-time situational awareness, empowering operators and managers to make informed decisions on the fly.

- Data-Driven Process Optimization: Eliminates guesswork by securely utilizing local data from IIoT devices, historians, and MES systems, ensuring process decisions are based on empirical evidence rather than opinion.

- Customized Optimization Models: Tailored solutions per recipe and production line that predict production events.

- 24/7 Intelligent Operations: Operates continuously without interruptions, serving as an electronic subject matter expert (eSME) that prescribes optimum process parameters for peak performance.

Transforming Industries with Intelligent Manufacturing

EXPRO AI™ is uniquely designed for continuous manufacturing processes and delivers value through improved product yield and quality.

"EXPRO AI™ represents a pivotal advancement in extrusion technology. By leveraging our process expertise and AI based modeling, our clients are able to achieve unprecedented levels of efficiency and product consistency," said Scott Krebs, President of the Wenger Group. "This technology transforms extrusion processes, making them smarter, more adaptive, and highly efficient.

About Wenger

Founded in 1935 in Sabetha Kansas, Wenger Manufacturing is the world's leading supplier of customized extrusion cooking and process systems used to process food, pet food, and aquatic feed. Wenger has offices, manufacturing, and service personnel in the Americas, Europe, and Asia to support customers globally.

About Extru-Tech

With extensive expertise in food, pet food, aquatic feed production, and automated process controls, Extru-Tech serves a global client base. The company provides comprehensive solutions ranging from ingredient handling to extrusion, drying, cooling, coating, and regulatory compliance support.

Marketplace

Contact Information:

Wenger®

15 Commerce Drive

Sabetha, Kansas 66534, USA

Phone: +1 785 284 2133

Email: [email protected]

Website: www.wenger.com

Extru-Tech, Inc.

100 Airport Road

Sabetha, Kansas 66534, USA

Phone: +1 785 284 2153

Email: [email protected]

Website: www.extru-techinc.com

Source: Wenger Group and Extru-Tech Inc.

You could be interested: Recovery of by-products in the manufacture of pet food

About company

About company

With a little ingenuity and a lot of hard work, Joe and his brother, Louis Wenger, founded the Wenger Mixing Company in a small town in Kansas (USA) in 1935. They then designed a machine that mixed molasses with dry feed ingredients and thus they began to produce pellets in 1948.

The novel idea of the Wenger brothers created a worldwide industry. Seventy-five years later, Wenger Manufacturing, Inc. remains a family business committed to innovation in the extrusion market.

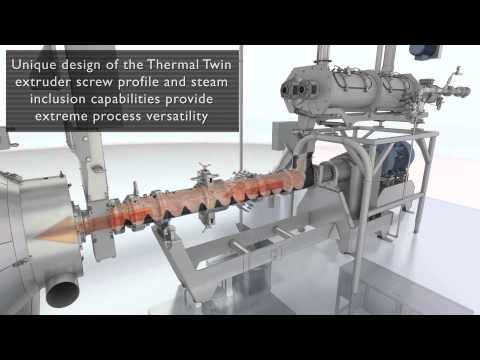

Today, Wenger offers a range of premium single-screw extruders, twin-screw extruders, dryers/coolers, coating systems, and control systems. A new generation of proud employees work for customer satisfaction in our multiple plants, in our world-class research and development center, and in sales and service offices around the world.

Wenger equipment is unmatched in quality. Perhaps even more important, it is the reputation we have built by having long-lasting partnerships with customers. Lasting because of our dedication, ingenuity, and responsiveness - and our promise to deliver on that commitment for generations to come.

Marketplace