The pet has become a true member of the family and the end customer, his owner, is increasingly oriented towards high-quality food in terms of well-being, quality and pleasure.

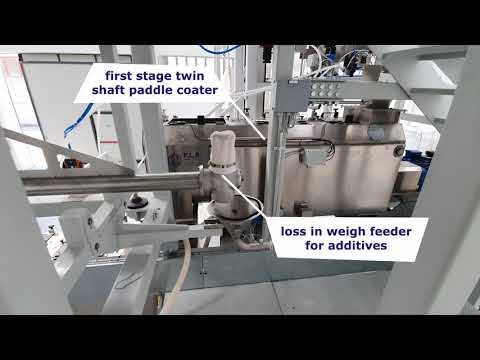

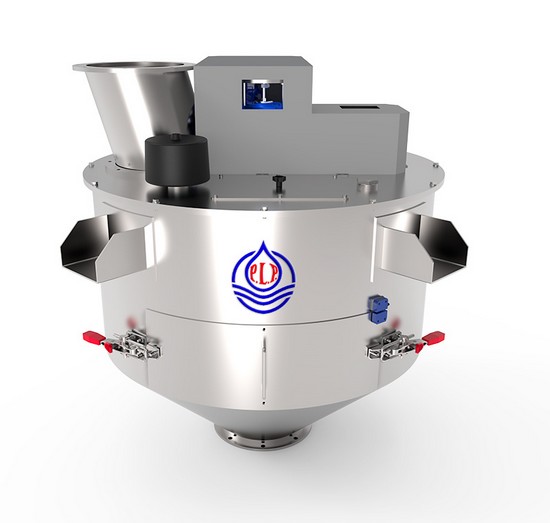

PLP takes up this challenge by developing systems that can translate market needs into real products. The treatment and coating system, patented as MASS SPIN COATER, is the new and revolutionary system for coating and adding additives onto solid products.

Through an integrated torsion transducer and a processor of Coriolis force data, the MSC is capable of identifying the mass delivery rate of solid prodcts (pelets, flours , croquettes). This permits a proportional control for adding doses of additives for the process. The MSC guarantees the uniformity of the finish products and thanks to reduced dimensions and weight, installation is made easy at any point of the system, be it on the transport piping in the drop, or at the end of production directly onto the vehicle load.

{{editor}}

It is used for applying either powder or liquid additives:

- Fat : for adding vegetable oils or fat in general. For adding molasses and other products largely used on the finished products

- Enzymes : for adding liquid enzymes and powder enzymes directly onto the finished product, to avoid cross contamination between the various products and to avoid waste due to degradation of the enzymes during the production of feed.

- Powder condensation : Fine powders, in an environment saturated with the same, cause serious problems such as explosions and subsequent fires , as well as serious respiratory problems for personnel and, last but not least, damage to the plant. which remain in the production cycle without creating further problems

- Humidification: For the treatment of humidification in raw materials with the addition of water and acidifiers with retroactive checks of humidity present in cereals

- Treatment after pelletizing : The addition of medicines in the production of feed is normally carried out in the mixing pase with contamination problems and loss of active ingredients due to mechanical and thermal stresses.

With the MSC it is possible to add antibiotics, coccidiostats, vitamins etc, whether in liquid or powder form. This process is possible thanks of the utilization of Seal4feed , a filming product from ARDA Innovations product of ARDA INNOVATIONS.

by PLP System

Source: All Pet Food

You could be interested: The importance of pet food coating: A technical overview

About company

About company

PLP Systems, founded in 1980, is a business reality specialized in dosing and weighing liquids and powders for production plants of pet food, feed, food for human consumption, and chemical products.

PLP Systems can supply complete systems for liquid and powder dosing control, continuous coating on finished products, microdosing, emulsifiers, motorized sprayers, flow meters, pumps, and filters.

In the pet food sector, PLP SYSTEMS has developed precise and reliable technological systems. It is one of the companies with the highest internationally recognized technological added value.

Please check the latest products in https://lnkd.in/eKs5wHP

We are available for any future information. Let's keep in touch!

Marketplace