From animal feed to construction materials, controlling particle size ensures quality, efficiency, and performance. This fundamental process makes modern manufacturing possible, affecting everything from your morning coffee to life-saving medicines.

So, what does pulverized mean? What are the applications? Read this article to explore how this unsung hero shapes the world, one particle at a time!

What is Pulverization?

Pulverization is the process of breaking down solid materials into fine particles to enhance their usability in various industries, where ingredients need to be processed into fine powders for better mixing and digestibility.

There are three primary types of pulverization:

- Crushing: The initial stage of size reduction, where solid materials reduce their size through mechanical forces such as compression impact and shear. Processing of minerals grains and dried plant materials makes frequent use of this method.

- Grinding: A secondary reduction process that refines crushed materials into smaller, more uniform particles. Grinding is essential in industries requiring consistent particle sizes, such as cement production, pharmaceuticals, and animal feed manufacturing.

- Milling: A finer grinding process that produces ultra-fine powders, often used in applications demanding high precision, such as nanomaterials, specialty chemicals, and high-performance food additives.

What Are the Applications of Pulverization?

Pulverization serves as a cornerstone technology across diverse industries:

Food & Feed Industry

In modern feed production, advanced pulverization techniques transform raw agricultural materials like corn, soybean meal, and wheat bran into highly digestible powders.

This particle size reduction is crucial for several reasons: it dramatically improves nutrient absorption in livestock and poultry, enhances feed conversion ratios (reducing overall production costs), and allows for uniform mixing of vitamins and supplements.

The aquaculture industry particularly benefits from precisely pulverizing, as fish and shrimp require optimally sized particles for efficient consumption. Recent advancements even enable customized particle size distributions tailored to specific animal species and growth stages.

In food manufacturing, pulverization creates the foundation for countless products. The manufacturing process of wheat depends on controlled pulverization methods for flour preparation, while sugar grinding produces confectionery items, and spice processing produces uniform flavor profiles. The technology also enables the production of instant food products through micronization, improving solubility and texture.

Marketplace

Pharmaceutical Industry

Pharmaceutical companies need exceptional accuracy control for their pulverization operations. Correct tablet manufacturing demands specific particle size control so the material can successfully get compressed and dissolve appropriately.

Inhalable medications depend on micron-scale powders for effective pulmonary delivery. Biotech applications use nano-pulverization to enhance drug bioavailability and create targeted delivery systems.

Chemical & Material Processing

Chemical and material processing industries utilize pulverization for catalyst production, polymer processing, and composite material manufacturing. Uniform particle sizes ensure predictable reaction kinetics and material properties. In construction, pulverized limestone and other minerals form the basis of cement, while the mining sector relies on ore pulverization for efficient mineral extraction.

Construction & Mining

Pulverization is widely applied in processing raw minerals, cement, and construction materials. Crushed and ground limestone, gypsum, and other aggregates are used in cement production and infrastructure development.

Recycling & Waste Management

Emerging applications in recycling and waste management demonstrate pulverization's environmental value. Modern shredding technology inputs construction waste, electronic garbage, and plastic waste to recover reusable components. Pulverization turns agricultural waste into functional organic amendments for soil while generating usable biofuel raw materials from it.

From ensuring livestock nutrition to enabling precision medicine and sustainable material cycles, pulverization technologies continue to evolve, addressing global challenges in food security, healthcare, and environmental sustainability.

FAMSUN's SWFL Series Pulverizer

As industries increasingly demand precision, efficiency, and adaptability in material processing, innovative pulverizer designs have become pivotal to meeting these challenges. At the forefront of this evolution is FAMSUN's SWFL Series Pulverizer Machines. Key advantages include:

- Multi-Industry Versatility: Designed for ultra-fine aquafeed grinding (100-250μm), this pulverizer also excels in pharmaceuticals, chemicals, food, and new energy materials, adapting to diverse industrial demands.

- High-Efficiency Grinding: Innovative serrated hammer blades and wave-like toothed rings maximize shearing force, while optimized airflow systems and rotor structures reduce energy waste. Automatic airflow adjustment ensures stable, high-yield performance.

- Precision Particle Control: Achieve exact fineness (100-250μm) via VFD-controlled grading impellers. Adjust linear speed and airflow paths to meet specific product requirements.

- User-Centric Design: Modular wear-resistant components (segmented toothed rings, stream-splitting covers) enable quick replacement, minimizing downtime.

- Safety & Reliability: G2.5 dynamic balance certification ensures vibration-free operation. Integrated sensors monitor temperature, sparks, and vibrations, triggering alerts for proactive safety management.

FAMSUN empowers industries to achieve finer, more uniform particle sizes by continuously optimizing pulverization technology. Visit our website now to find out more pulverizer machine solutions or speak to our experts to see which one is best for you!

Source: FAMSUM

You could be interested: Grinding: A fundamental point in the manufacture of extruded dry food for cats and dogs

About company

About company

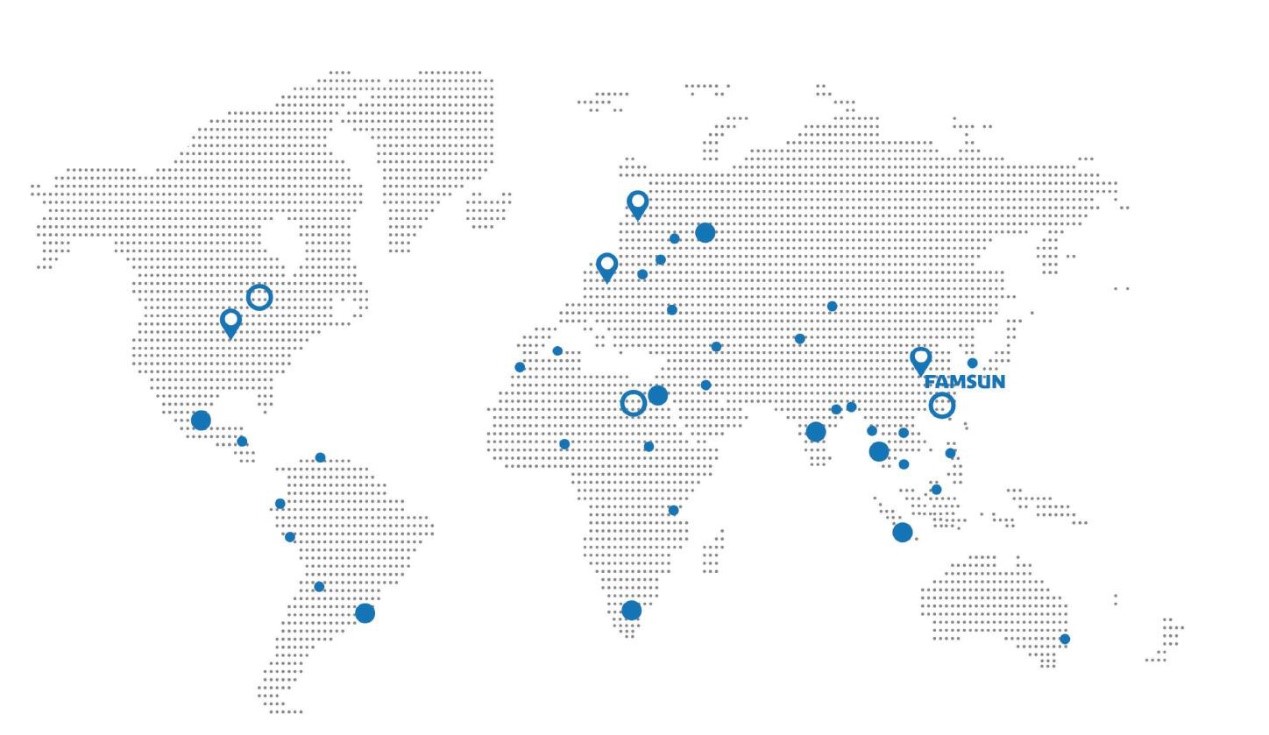

Office & Factory

Global Presence

Company introduction

FAMSUN Group Co. Ltd., headquartered in Yangzhou, China, is a global technology partner and the integrated solution provider of plant, equipment, and services in feed manufacturing, grain milling, grain handling and storage, oilseed processing, food processing, steel structure construction, and industrial automation.

FAMSUN has over 2,800 employees, including 900 technicians and engineers. Backed by its strong R&D capabilities, FAMSUN has developed more than 120 series (700 models) of quality feed and grain processing machines and is capable of delivering a wide range of turnkey projects from farm to table and in associated industries.

FAMSUN operates five production sites as well as over 50 agencies, sales & service stations, and spare parts warehouses around the world. FAMSUN has successfully completed over 8,600 referenced projects in more than 140 countries.

Our vision is to provide optimal technology solution and make life better for all. We value innovation, hard work, dedication, integrity, quick response, and team-work.

FAMSUN Pet Food division is committed to machinery research, manufacturing, project engineering, factory construction and integrated solutions in pet food industry, create values for customers. As a leading integrated solution provider in pet food industry, FAMUSN undertakes pet food (dry food, semi-moist, extruded treats) and cat litter turn-key project.

Our corporate leads the market by technology, with experienced elite team and European & USA technical experts, through continuous innovation, to provide customers with professional, safe, systematic extruded pet food production solutions, customized environment-friendly and intelligent factory with high standards, high quality, high efficiency. We won the trust and praise from our partners/customers worldwide.

8,600+ referenced projects in 140+ countries. 50+ agencies, sales & service stations, and spare parts warehouses worldwide closed to customers. Five production bases, one in Egypt and four in China. Total of 74.07 hectares of manufacturing and distribution capacity. 2,800+ employees work in sales, customer service, engineering, R&D, production, and logistics. More than 5% of annual revenue invested in R&D, every year equipment is marked by CE and ATEX sym.

Noticias de la empresa

25/04/2022