March 1, 2022

This document was prepared by the Technical Committee ISO/TC 293, Feed machinery, developed by ISO/TC 293/WG1 (terminology), in which more than 40 members from China, USA, Germany, Switzerland, Iran, Pakistan, the Republic of Korea, Canada, etc. worked together for nearly six years. The project leader and workgroup convenor was Weiguo Wang, professor of Henan University of Technology, China.

The Feed machinery terminology standard harmonizes terminology used by manufacturers globally and will supply the basic terms for developing other feed machinery standards and the global feed industry users.

Professor Weiguo Wang speaking on the Third Plenary Meeting of ISO/TC293 on 20th Oct. 2021.

About ISO/TC 293

Standards are the international language of business. The International Organization for Standardization (ISO) develops and publishes international standards with global expert input. The feed industry, as an important part of the food chain and responsible for producing safe, high-quality animal feed to support safe, animal-derived foods, also needs a common language to facilitate international trade and help ensure the manufacture and delivery of safe, reliable products. Initiated by industry experts in China, the Technical Committee ISO/TC 293, Feed Machinery, therefore, was established in 2014. The scope of this committee includes standardization of single feed machines, processing systems and complete production lines.

The participating (voting) members of the Technical Committee ISO/TC 293, Feed Machinery represent 14 countries: Canada, China, Denmark, France, Germany, Iran, Republic of Korea, Pakistan, Romania, Spain, Switzerland, Turkey, the United Kingdom and the United States. Observing members represent 14 countries: Argentina, the Czech Republic, Finland, Hungary, Indonesia, Italy, Japan, Mali, Malta, Peru, Poland, Saudi Arabia, Sweden and Uzbekistan.

The ISO/TC 293 currently is administered by the China National Technical Committee on Feed machinery and is developing standards in the areas of terminology, safety and the hygiene of feed machinery.

New standards proposed

The Technical Committee ISO/TC 293, Feed Machinery held its third plenary meeting of ISO/TC293 on 20-21 Oct. 2021 to discussed critical issues to enhance the feed machinery and feed manufacturing industries. The hybrid event, with the in-person meeting at FAMSUN Group, Yangzhou, China, was officially opened by Professor Fengcheng Wang, ISO/TC 293 Chairman. He welcomed over 30 delegates from the participating countries of China, Canada, Germany, Iran, Pakistan, Switzerland, Turkey, and the United States, and its two connection organizations: ISO/TC34/SC10 Animal Feed Technical Committee and ISO/TC34/SC17 Food Safety Management System Technical Committee.

Marketplace

Professor Wang reviewed the work and the progress of ISO/TC 293 since the second plenary meeting, thanked the workgroups for their collaboration and contributions during the pandemic. Delegates discussed the proposed topic and scope of the international standard project of "Safety requirements for feed machinery", the work plan of the international standard project of "Cross-contamination control of feed production lines", and the 'Recommendations on drafting international standards of dust-explosion-proof for feed processing systems' that proposed by delegates from FAMSUN Group.

'We will encourage the world's most outstanding experts – as many of them as possible – to join us in the ISO/TC 293 and offer their opinions on behalf of their country's industry in the coming years,' said Pengfei Zhang, Chief of the Chinese delegation and Vice President of FAMSUN R&D Institute.

'The greater the international participation, the stronger the feed machinery standards will be, and the better they will contribute to the global food future,' he said.

Source: Famsun Group

You could be interested: RBS Baked Pet Food Systems: Optimized, Automated Solutions for Baked Pet Treats and Baked Kibble (Part 2)

About company

About company

Office & Factory

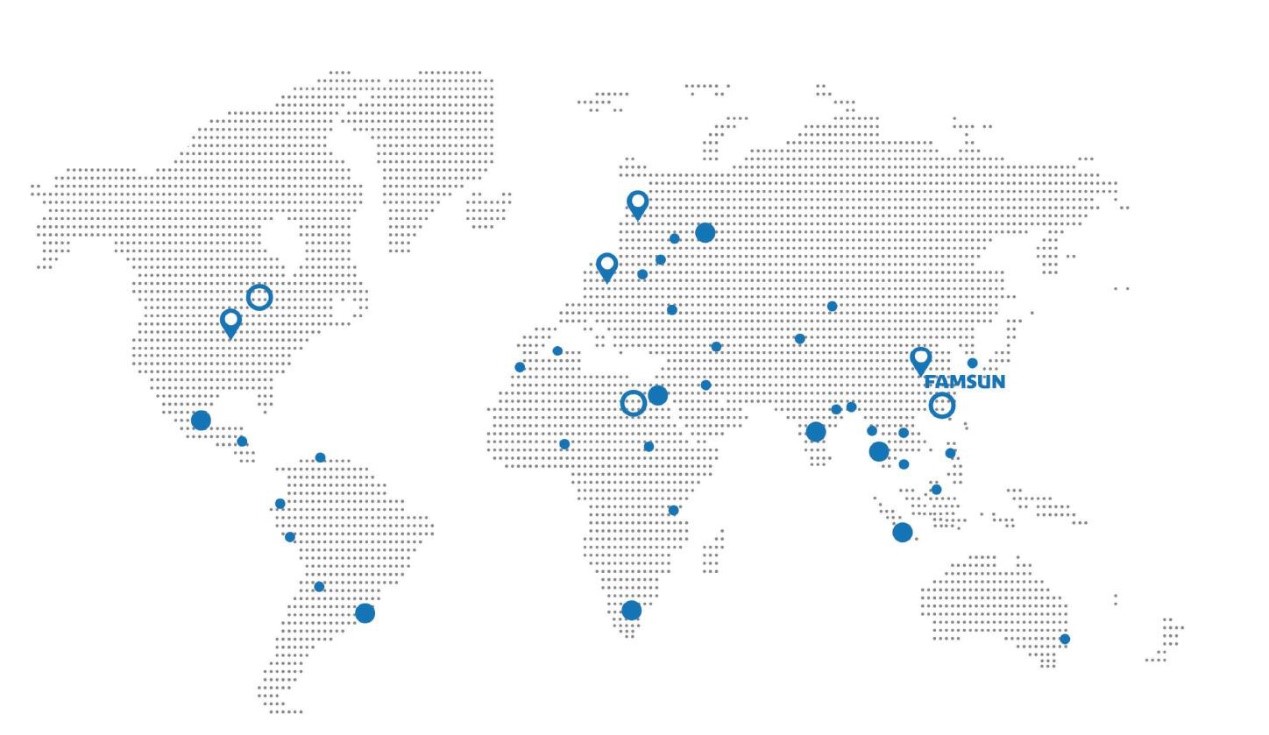

Global Presence

Company introduction

FAMSUN Group Co. Ltd., headquartered in Yangzhou, China, is a global technology partner and the integrated solution provider of plant, equipment, and services in feed manufacturing, grain milling, grain handling and storage, oilseed processing, food processing, steel structure construction, and industrial automation.

FAMSUN has over 2,800 employees, including 900 technicians and engineers. Backed by its strong R&D capabilities, FAMSUN has developed more than 120 series (700 models) of quality feed and grain processing machines and is capable of delivering a wide range of turnkey projects from farm to table and in associated industries.

FAMSUN operates five production sites as well as over 50 agencies, sales & service stations, and spare parts warehouses around the world. FAMSUN has successfully completed over 8,600 referenced projects in more than 140 countries.

Our vision is to provide optimal technology solution and make life better for all. We value innovation, hard work, dedication, integrity, quick response, and team-work.

FAMSUN Pet Food division is committed to machinery research, manufacturing, project engineering, factory construction and integrated solutions in pet food industry, create values for customers. As a leading integrated solution provider in pet food industry, FAMUSN undertakes pet food (dry food, semi-moist, extruded treats) and cat litter turn-key project.

Our corporate leads the market by technology, with experienced elite team and European & USA technical experts, through continuous innovation, to provide customers with professional, safe, systematic extruded pet food production solutions, customized environment-friendly and intelligent factory with high standards, high quality, high efficiency. We won the trust and praise from our partners/customers worldwide.

8,600+ referenced projects in 140+ countries. 50+ agencies, sales & service stations, and spare parts warehouses worldwide closed to customers. Five production bases, one in Egypt and four in China. Total of 74.07 hectares of manufacturing and distribution capacity. 2,800+ employees work in sales, customer service, engineering, R&D, production, and logistics. More than 5% of annual revenue invested in R&D, every year equipment is marked by CE and ATEX sym.

Noticias de la empresa

25/04/2022