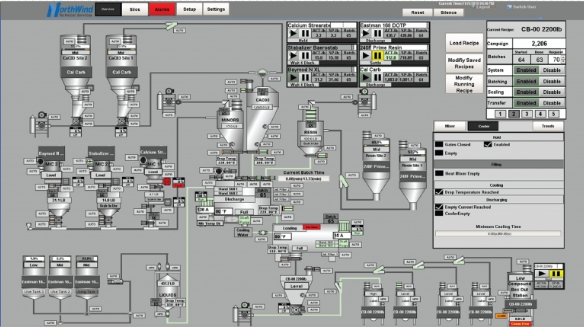

The control system's human machine interface (HMI) is the connection between an operator and each machine. HMIs provide processing data for operator and maintenance personnel to interact with the equipment. Traditional HMI graphics that are full of color, moving components, and detail are visually impressive but inefficient as the colors and animations detract from the actual data needed. Plant operators and maintenance personnel must quickly identify critical process information and high-performance graphics (HP graphics) allow them to do just that. By understanding HP graphics and how they help operators identify critical information, companies can confidently make the shift to new technology.

High-Performance graphics vs traditional HMI graphics: Visual Differences

HP graphics reduce troubleshooting time by highlighting pertinent information. While maintaining a visual representation of the equipment and system, HMIs provide a user with helpful alerts and status information. In traditional graphics, the proliferation of color is distracting. HP graphics reserve bold colors and movement only for instances when attention is needed.

For example, if a receiver refill is disabled and the receiver is below low level, the low-level indication is visible, but the banner will be gray instead of yellow. This color change allows the operator to better focus on critical information.

How to transition an HMI to HP Graphics

It's possible that some personnel will not be initially accepting of the new graphics. The biggest push back when upgrading to HP graphics generally comes from operators that have been working with traditional HMIs for a long time and are used to a lot of color and detail on the screen. The grayscale color scheme brings a misconception that the new HP graphics will make it harder to understand what is happening in the system. However, with more muted tones, alerts and warnings are very easy to spot, providing the user a very readable HMI.

HMI alerts and alarms that benefit from HP graphics include:

- System Status

- Device Faults

- Low Feed Rate

- Ingredient Setpoints

- Trends

- Process Variables

- Batch Details

Implementing HP graphics on the plant floor

NorthWind has moved to HP graphics as a standard for all projects. With this change, we have maintained the same overall feel, while providing a more readable HMI. Our HOA banners, menu bar, and feed point objects maintain similar aspects to our old graphics package but are now more visible when data is most critical.

Marketplace

A lot of the changes incorporate the intentional use of color and adding dynamic visibility – displaying exactly what information the user needs to see at the critical moment. To further ease troubleshooting, reference points are built into the HMI, PLC, and electrical drawings, allowing personnel to quickly find the information they need.

NorthWind trains and supports customers through the transition to HP graphics – from the startup process to complete integration. We also transition existing HMIs to HP graphics for a streamlined user experience across the entire manufacturing plant.

At NorthWind, we're all about data. The efficiencies gained with the new graphics are everything we're about – accurate process data in the most usable form.

Source: Northwind Technical Services LLC

You could be interested: RBS Baked Pet Food Systems: Optimized, Automated Solutions for Baked Pet Treats and Baked Kibble (Part 2)

About company

About company

NorthWind’s skilled team of engineers, programmers, and technicians have extensive process experience in addition to programming and design expertise in a wide range of industries.

NorthWind provides automation solutions for manufacturing facilities throughout the world. We also offer industrial electrical installation services in the USA.

Our headquarters is located in Sabetha, KS. The majority of employees and all panel fabrication activities are located at this facility. A second location was established in San Jose, Costa Rica in June of 2019 in order to better serve customers in Latin America. The Costa Rica office houses four employees that work in Service, Sales, and R&D.

Our skilled team of engineers, programmers, and technicians have extensive process experience in addition to programming and design expertise in a wide range of industries. The NorthWind PlantLOGIX™ software suite streamlines and simplifies programming, management, and maintenance of industrial processes while increasing visibility into what’s happening on the factory floor. State-of-the-art office technology and expertise allows NorthWind to provide programming and support services to clients anywhere in the world in a multitude of industries.

Our U.L. Listed control panel shop is located in a 10,000 sq. ft. climate-controlled facility that is fully-equipped to fabricate, test, and ship control panels of any size. High standards and advanced manufacturing technologies used by NorthWind ensure that control panels are delivered onsite on time and ready to be installed.

NorthWind strives to achieve high standards that meet customer needs and company stability. The company has been Control Systems Integrators Association (CSIA) certified since 2010 and continues to employ CSIA’s Best Practices and Benchmarks in order to provide the best value to its customers, combining technical proficiency with sound business practices.

NorthWind is also an accomplished Rockwell Automation Solution Partner, providing proven services and solutions that meet our customers’ automation needs. Finally, NorthWind was named CSIA Integrator of the Year in 2019, a prestigious national award given to controls system integrators that demonstrate cutting-edge technology and cost effective solutions for manufacturers