There was a key change once a continuous coating test plant was developed in our company that can reproduce the full capacity of the industry demands, to minimize the difference in results between a laboratory test compared to actual production.

This internal continuous coating test plant is used for:

- Technological innovation of PLP and know-how to compete in the market with the application of pellet coating.

- Customers looking for creative applications are available to perform testing and developing new products for your pet food by coating them with powders or flakes such as spices, vegetables, cheese, flavors, nutritional agents, etc. Too to coat semi-moist or baked pet food.

- Customers who want to test PLP technology before purchasing the system can perform the test of the complete coating line.

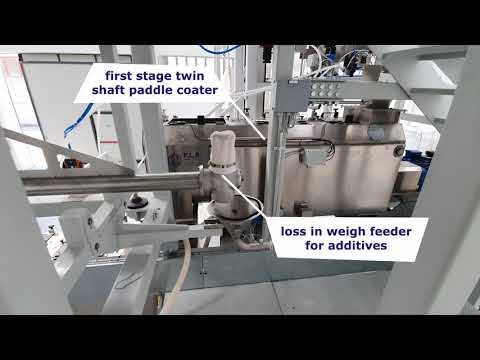

The pilot plant can be adapted for different products with a production capacity from 300 kg / h to 15 ton / h, managing different densities. It is equipped with a precise gravimetric continuous dosing of the main product (croquettes) carried out by means of a weighing tape or a weighing thread. Dosing of liquids by pump and flow meter and dosing of powders by weight loss feeders.

All controlled by the automation and proportional dosing adjusted by frequency control drives. The test plant can be integrated with 3 different PLP coating technologies:

DRUM ROTARY; COVER WITH DOUBLE AXLE BLADES; MASS SPIN COATER.

ROTARY DRUM

The latest development over the more traditional rotary drum, this machine is specially recommended for semi-wet products, small extruded or granulated pellets and lower production capacity. The special corrugated shape of the drum increases the rotation of the product, at the same time protects it from damage and reduces waste inside the machine, making it a perfect machine to be used in food application or with special kibbles for pet food.

CONTINUOUS COVER WITH DOUBLE AXLE PADDLES

It is our most widely used machine for standard pet food production and has received the majority of R&D improvements during the last years. There are different models that can cover all required production ranges with high liquid inclusion rates or fats. The focus of the machine is the retention time and this is achieved by regulations of speed independent of the axles, internal dampers and automatic check valve in the output of the product. The retention time in standard pet food production it can reach up to 200 seconds.

Marketplace

MASS SPIN COATER

Compact continuous cover used to add micro liquids up to 1%. The MSC integrates a continuous precision weighing technology, based on Coriolis forces. Thanks to a nozzle special is able to obtain a perfect homogeneity even when the inclusion rates are less than 0.1%.

Source: PLP Systems

You could be interested: Innovating together: A new development for the premix pet food industry

About company

About company

PLP Systems, founded in 1980, is a business reality specialized in dosing and weighing liquids and powders for production plants of pet food, feed, food for human consumption, and chemical products.

PLP Systems can supply complete systems for liquid and powder dosing control, continuous coating on finished products, microdosing, emulsifiers, motorized sprayers, flow meters, pumps, and filters.

In the pet food sector, PLP SYSTEMS has developed precise and reliable technological systems. It is one of the companies with the highest internationally recognized technological added value.

Please check the latest products in https://lnkd.in/eKs5wHP

We are available for any future information. Let's keep in touch!