PLP Systems

https://www.plp-systems.com/

PLP Systems

About the company

PLP Systems, founded in 1980, is a business reality specialized in dosing and weighing liquids and powders for production plants of pet food, feed, food for human consumption, and chemical products.

PLP Systems can supply complete systems for liquid and powder dosing control, continuous coating on finished products, microdosing, emulsifiers, motorized sprayers, flow meters, pumps, and filters.

In the pet food sector, PLP SYSTEMS has developed precise and reliable technological systems. It is one of the companies with the highest internationally recognized technological added value.

Please check the latest products in https://lnkd.in/eKs5wHP

We are available for any future information. Let's keep in touch!

Products

Company News

Mixing

Mixing

4+ MIN

06/02/2025

The Role of Premixing and Homogenization

The process of incorporating different liquids into a batch mixer is a critical step in various industrial applications.

Understanding the chemical properties of the liquids used, as well as employing appropriate mixing techniques, is essential to prevent issues like stratification, poor homogeneity, lump formation, and increased energy consumption.

Batch mixers are widely used in industries such as food processing, pharmaceuticals, animal feed, Pet food, chemical and materials manufacturing to blend solids and liquids into a homogeneous mixture. However, achieving uniform distribution of liquids within the solids can be challenging, especially when dealing with immiscible liquids like oil and water. The homogeneity of the final product, often measured by the Coefficient of Variation (CV), is influenced not only by the type of mixer but also by the properties of the liquids involved.

Discover the importance of premixing immiscible liquids using dedicated homogenization equipment to enhance the final product quality and operational efficiency.

UNDERSTANDING LIQUID MISCIBILITY

The ability of liquids to mix and form a single homogeneous phase is governed by their chemical properties. Liquids that can combine and form a new, uniform liquid are termed 'miscible'. Conversely, liquids that resist mixing and instead form separate layers are referred to as 'immiscible'. A classic example of immiscible liquids is oil and water, which naturally separate due to differences in polarity and density.

MISCIBLE LIQUIDS

IMMISCIBLE LIQUIDS

CHALLENGES IN MIXING IMMISCIBLE LIQUIDS

When immiscible liquids like oil and water are added separately to a batch mixer, several problems can arise:

Stratification: Immiscible liquids tend to form separate layers on the surface of the solid particles, leading to poor distribution throughout the mash.

Poor homogeneity: The inability of immiscible liquids to mix results in high CV values, indicating significant variation in the composition of the final product.

Lump formation: The separation of liquids can lead to the formation of lumps, which further degrades the quality of the mixture.

Reduced product quality: Inconsistent mixing can compromise the structural integrity and overall quality of the final product.

Increased mixer and transport contamination: Immiscible liquids can adhere to the interior surfaces of the mixer and transport equipment, leading to contamination and requiring more frequent cleaning.

Higher energy consumption: Poorly mixed liquids can cause the mixer to work harder, increasing energy consumption and operational costs.

DOSING AND HOMOGENISING

THE EML SERIES HOMOGENIZER BY PLP SYSTEMS

Achieving homogeneity in a batch mixer when working with immiscible liquids is a complex challenge that requires careful consideration of the liquids' properties and the mixing techniques employed. That's why PLP Systems has created The EML series homogenizer machine, used in all areas where there is a need to mix and emulsify various liquids or powder dispersions. Placed below the threshold of a tank, thanks to the pumping effect, allows the circulation of liquids in the container.

The intense cutting effect resulting from the combination of mechanical and hydraulic processing of the 'rotor' and 'stator', a powerful 'shear' effect is generated on the product. This process ensures a highly mixed consistency and perfect homogeneity, ensuring high-quality results for the finished product.

Comparision of liquid feed separation times. The sample on the left was obtained using a traditional mixer, while the one on the right was obtained using our EML Homogenizer.

Fig. 1-2, 70% vegetable oil; 30% H₂O. Fig. 3-4, 40% molasses, 40% vegetable oil, 20% H₂O. Comparision of liquid feed separation times. The sample on the left was obtained using a traditional mixer, while the one on the right was obtained using our EML Homogenizer.

By premixing immiscible liquids using a EML homogenizer, manufacturers can overcome many of the issues associated with direct mixing, leading to improved product quality. As industries continue to demand higher standards of quality and efficiency, the adoption of advanced mixing and homogenization techniques will become increasingly important for different industries.

EML SERIES – PLP HOMOGENIZER

PLP Systems specializes in both liquids and powders, with a special focus on the pet food and feed industries. An important area for PLP is the accurate management of liquids and powder for feed production, with a specific focus on post-pellet coating. This process involves adding micro-liquids such as enzymes, vitamins, flavors, probiotics amd yeast to the pellets, aiming to enhance their quality.

Whether you're looking to improve your current production line or explore innovative methods to increase product appeal, our technologies offer the reliability and excellence you need.

Need more information or want to dive deeper into our liquids dosing and mixing systems?

We're here to provide tailored solutions and answer all your questions.

Call us today at +39 0523 891 629 or email us at [email protected] for a free consultation.

We're here to help you find the perfect solution for your needs!

Source: PLP Systems

Coating

Coating

4+ MIN

11/11/2024

The importance of pet food coating: A technical overview

What is kibble coating?

Pet food coating, also commonly referred to as palatability of the kibble, is a crucial practice in the pet food industry, used to enhance the energy and nutritional value of the food.

This technique involves the addition of animal and vegetable fats and oils, which are essential for meeting the specific energy requirements listed on product labels. Besides improving palatability, coating with oils provides essential fatty acids for your pet's health and enhances the texture of the kibble.

When and how are fats and oils added?

Some of these fats and oils can be incorporated during the mixing or conditioning phases before extrusion. However, excessive liquid addition at this stage can compromise the formation of the kibble. Therefore, the best method is to apply the lipids after the kibble has been formed, typically after the drying phase and before cooling. Commonly used fats include: chicken oil, lard, pork fat, and fish oils. Vegetable oils such as canola, sunflower, soybean, palm, and coconut are also widely used, depending on local availability and manufacturer preferences.

For dog kibble, the typical oil addition range varies based on factors such as geographic location, age, and activity level of the animal. Generally, oil content ranges from a minimum of 1% to a maximum of 14% of the total kibble weight, with some exceptions for working dogs, where oil content can exceed 20%. In contrast, oil inclusion for cat kibble usually does not exceed 5%.

In addition to oils, other additives are applied during the coating process, primarily flavor enhancers and palatability agents. These are often based on hydrolyzed meat, commonly known as "digest", and are available in both liquid and powder form.

The importance of coating

The taste of pet food, especially for cats, is a critical factor for manufacturers, as pet owners are more likely to repurchase a brand if their pets enjoy the food. While ingredient quality is undeniably important, the technology used in production is equally significant. Achieving uniformity is essential to ensure that the entire surface of the kibble is evenly coated, resulting in a consistent flavor throughout each piece.

Oils, in addition to playing a key role in food preservation, provide a uniform color. Inconsistent oil absorption can cause some kibble pieces to appear darker, leading to a perception of lower quality.

This is why precise and careful application of coating is fundamental in pet food production.

Let's explore the most commonly used technologies in the market and which one represents the best solution.

Different technologies for kibble coating

Coating technologies can be classified into two categories: batch coating and continuous coating, each with its own subcategories:

Batch Coater: This method uses a vertical or horizontal mixer to move a weighed batch of kibble, which is then sprayed with a specific amount of oils and flavors. This is generally considered outdated technology that does not ensure good uniformity.

Vacuum Batch Coater: Similar to the batch coater, this technology generates a vacuum during the application process. The vacuum is gently released after the oils are sprayed, allowing the oils to penetrate deeply into the porous kibble. This is the only technology suitable for applying high oil inclusions above 20%. However, when the formula requires low oil additions below 8% (within a range of 5-10% depending on various factors), it can lead to poor uniformity.

Continuous Drum Coater: In this method, the kibble continuously passes through a rotating drum, and additives are sprayed over a large surface area of the food. This is considered an outdated and more economical coating solution. The main limitations of this technology include low flow capacity (typically no more than 3 tons per hour), limited oil addition, and a short retention time during the coating and mixing phases.

Continuous Disc Coater with Spray: In this process, the kibble is continuously weighed and passes through a vertical chamber with a rotating disc that sprays the liquids. The spraying occurs from the center outward, and the kibble falls in a cascading motion, where it is coated by the liquid spray. While this technology can achieve good uniformity, it has two main drawbacks: a tendency to accumulate material in the disc spray chamber and the limitation of a single spray phase, while the market typically requires multiple phases for oils, liquid flavors, and powdered additives.

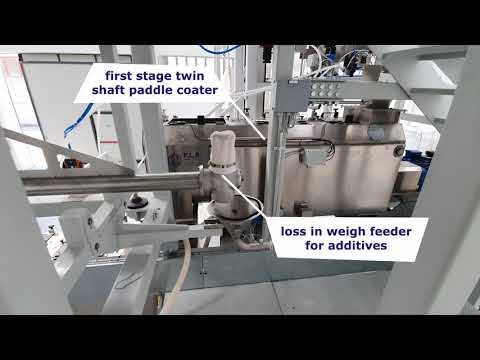

Continuous Paddle Coater: PLP Systems offers a range of advanced coating technologies, but the MT Paddle Coater stands out as the ideal solution. This innovative system features a double continuous paddle shaft that ensures gentle product handling, precise dosing, and automated retention time adjustments.

The system is equipped with motorized SMOG atomizers positioned at the top, ensuring optimal distribution across various application phases. It can achieve micro inclusions as low as 0.01% with excellent uniformity, adhering to the highest Coefficient of Variation (CoV) standards. Additionally, it supports oil addition up to 15%, making it a versatile and efficient solution for precision coatings.

PLP Systems specializes in both liquids and powders, with a special focus on the pet food and feed industries.

Making kibble tasty and appealing with palatants, whether liquid or powdered, loved by animals is one of our primary goals.

Our cutting-edge solutions ensure that your products stand out in a competitive market, offering superior taste and quality that animals adore.

Whether you're looking to improve your current production line or explore innovative methods to increase product appeal, our technologies offer the reliability and excellence you need.

Need more information or want to dive deeper into our coating systems?

Don't hesitate to contact our experts. We're here to provide tailored solutions and answer all your questions.

Call us today at +39 0523 891 629 or email us at [email protected] for a free consultation.

We're here to help you find the perfect solution for your needs!

Source: PLP Systems

Market Information

Market Information

3+ MIN

19/03/2024

PLP Systems: International Fairs and Conferences continue in 2024

The 2023 trade show season has been a great success for PLP Systems, leader with its liquid and powder dosing technologies.

Operating across various sectors such as: livestock, milling, pet food, aqua feed, enology, food & beverage, fertilizers, seeds, chemicals, cosmetics, and the concrete industry, the company participated in nine fairs across Europe, Asia, and South America, covering all the sectors in which it operates and sharing its expertise and innovation.

Now, the company is gearing up for an equally eventful 2024, offering a comprehensive range of machinery and components for dosing, greasing, mixing, spraying, and homogenizing liquids, powders and additives. PLP Systems looks forward to meeting clients, partners, and professionals at various events worldwide.

CFIA, Rennes: March 12-14. As one of the most important agri-food fairs in France, PLP Systems will showcase its expertise in food coating and micro-dosing technologies. Participants will have the opportunity to discover the MDP batch micro-dosing system for powders.

Victam, Bangkok: March 12-14. PLP Systems is excited to participate in this comprehensive trade show and conference for the animal protein production supply chain and livestock industry in Asia. Managing Director Marco Prati will hold two conferences organized by International Pet Food.

On March 11th, he will provide insights into our coating technologies at the Petfood and Aquafeed Extrusion Conference.

On March 13th, he will provide insights on handling minor ingredients and additives in feed production at the Build My Feedmill conference at the Build my Feedmill conference.

GIC, Piacenza: April 18-20. The only Italian fair dedicated to the concrete industry is an opportunity for PLP Systems to showcase its latest technologies for complete premix production lines and precise dosing systems for liquids, powders, and additives.

INTERZOO, Nuremberg: May 7-10. Returning after a two-year wait, INTERZOO is one of the world's major pet food fairs. PLP Systems will present its flagship technology for the pet food sector: the MT, a complete machine for coating and greasing pellets, kibbles, and other granular products.

SOLIDS, Parma: June 5-6. Following the success of the previous edition, SOLIDS Italy returns as a powerful network of professional fairs for granular material, powders, and bulk solids technologies. PLP Systems looks forward to presenting its micro-dosing technologies.

Foro Mascotas Pet Food Internacional, Guadalajara: June 27-28. Participating in one of the most important pet food industry fairs in Latin America, PLP Systems is eager to explore the latest trends in this evolving and growing market.

CIPAL, Buenos Aires: September 25-26. Organized by All Pet Food, this congress aims to update on the latest trends in the Latin American pet food industry. PLP Systems will present its innovations, including high-precision dosing systems and machines for coating and greasing products.

EUROTIER, Hanover: November 12-15. The world's largest event dedicated to animal production, provides an opportunity for PLP Systems to assert its leadership in providing complete and efficient solutions for the rapidly evolving global livestock industry.

The 2024 trade shows will once again be an opportunity for PLP Systems to strengthen its position with dosing, greasing, spraying, and more.

The company looks forward to meeting you in person in Europe, Asia, and Latin America!

Source: PLP Systems.

Market Information

Market Information

2+ MIN

09/11/2023

PLP Systems: When quality meets experience

The company focuses on developing customized systems talored to clients' specific needs, creating solutions for each project. PLP Systems invests as well heavily in R&D each year, to create new concepts and continuously improve existing technologies. Their dedicated team of engineers and techniciand are experts in dosing, mixing, spraying, coating and handling liquids and micro powder additives. Through R&D, PLP identifies key requirements and potential areas for innovation, they then design, test and optimize new solutions to meet demands for higher productivity, quality and sustainable processing. With a commitment to quality, PLP Systems builds all equipment to the highest standards. Each system is meticulously engineered and constructed from high-grade components to ensure maximum efficiency, reliability and a long operating life. Stringent quality control procedures and testing guarantee consistent performance and safety of all machines before shipping. After installation, PLP Systems provides full after-sales support and service to assist customers in getting the most from their investment. By establishing open and enduring customer relationships built on trust and understanding, PLP is able to support the long term success of their clients. Recently the company has increades its participation in fairs both in Italy and around the world, expanding its know-how, expertise and technologies to an even wider and more diversified audience. PLP Systems is convinced that through direct and human contact, lasting and solid relationships can be established. By continuously enhancing their knowledge and skills, PLP Systems will continue provide innovative and high-quality solutions to meet the changing needs of the pet food and feed industries. About PLP Systems By: PLP Systems

Coating

Coating

2+ MIN

20/06/2023

MASS SPIN COATER - Revolutionary patented system

The pet has become a true member of the family and the end customer, his owner, is increasingly oriented towards high-quality food in terms of well-being, quality and pleasure. PLP takes up this challenge by developing systems that can translate market needs into real products. The treatment and coating system, patented as MASS SPIN COATER, is the new and revolutionary system for coating and adding additives onto solid products. Through an integrated torsion transducer and a processor of Coriolis force data, the MSC is capable of identifying the mass delivery rate of solid prodcts (pelets, flours , croquettes). This permits a proportional control for adding doses of additives for the process. The MSC guarantees the uniformity of the finish products and thanks to reduced dimensions and weight, installation is made easy at any point of the system, be it on the transport piping in the drop, or at the end of production directly onto the vehicle load. It is used for applying either powder or liquid additives: - Fat : for adding vegetable oils or fat in general. For adding molasses and other products largely used on the finished products - Enzymes : for adding liquid enzymes and powder enzymes directly onto the finished product, to avoid cross contamination between the various products and to avoid waste due to degradation of the enzymes during the production of feed. - Powder condensation : Fine powders, in an environment saturated with the same, cause serious problems such as explosions and subsequent fires , as well as serious respiratory problems for personnel and, last but not least, damage to the plant. which remain in the production cycle without creating further problems - Humidification: For the treatment of humidification in raw materials with the addition of water and acidifiers with retroactive checks of humidity present in cereals - Treatment after pelletizing : The addition of medicines in the production of feed is normally carried out in the mixing pase with contamination problems and loss of active ingredients due to mechanical and thermal stresses. With the MSC it is possible to add antibiotics, coccidiostats, vitamins etc, whether in liquid or powder form. This process is possible thanks of the utilization of Seal4feed , a filming product from ARDA Innovations product of ARDA INNOVATIONS. by PLP System Source: All Pet Food

Coating

Coating

2+ MIN

24/11/2022

Continuous Coating: High retention time

The coating of pet food croquettes is an important phase of the process, as the external covering of a croquette is the initial contact with the animal as well as the main point of reference that the customer will trust. The coating phase must be carried out to: Obtain color homogeneity in all croquettes Reduce oil loss and greasy look and feel Improve the distribution and homogeneity of palatant and flavoring additives. Reduce disinfection problems in the coating process CONTINUOUS COATING BENEFITS Pro: High-level of homogeneity (CV) can be obtained even with the addition of low amounts, being more flexible and kind with the production and the product itself. Requirements for a successful application: Performing croquettes dosing: The dosage must be carried out using continuous gravimetric weighing systems, not volumetric. The variation of the incoming product flow must be adjusted and stabilized by the proportioner to have a uniform output. Covering: The team must be as gentle as possible with the product but should also guarantee good mixing homogeneity. The retention time is essential when high amounts of oils are added, and should not be less than 60 seconds. Atomization: Continuous atomization is a real challenge, especially when the product flow varies. Standard nozzles are always exposed to dirt and blockages. PLP recommends SMOG Technology for perfect atomization in any condition and viscosity. *Typical diagram of a continuous coating installation In addition to the points mentioned above, there is another very important factor during the coating process, which will result in a more homogeneous final product: HOLDING TIME Homogeneity is also related to the absorption of fat by croquettes. As for the process, this can be increased thanks to the combination of heat and croquette retention in the mixing phase in the covering. The MT series is equipped with heating chambers that maintain a controlled temperature inside the machine, while the retention time is increased by: Adjustment of the angles of the vanes Adjustment of the speed of the rotary axes Internal shock absorbers RETENTION GATE PLP has developed an automatic check gate, located at the outlet of the machine. It is suitable for stopping the croquette flow and releasing it when product accumulation reaches a certain level inside the machine. Thus, it significantly increases the retention time, up to 180 seconds inside the MT machine. For more information visit the PLP Systems WEB or contact this EMAIL. Source: PLP Systems

Dosing

Dosing

2+ MIN

30/08/2021

PLP Systems pilot plant for continuous coating

There was a key change once a continuous coating test plant was developed in our company that can reproduce the full capacity of the industry demands, to minimize the difference in results between a laboratory test compared to actual production. This internal continuous coating test plant is used for: Technological innovation of PLP and know-how to compete in the market with the application of pellet coating. Customers looking for creative applications are available to perform testing and developing new products for your pet food by coating them with powders or flakes such as spices, vegetables, cheese, flavors, nutritional agents, etc. Too to coat semi-moist or baked pet food. Customers who want to test PLP technology before purchasing the system can perform the test of the complete coating line. The pilot plant can be adapted for different products with a production capacity from 300 kg / h to 15 ton / h, managing different densities. It is equipped with a precise gravimetric continuous dosing of the main product (croquettes) carried out by means of a weighing tape or a weighing thread. Dosing of liquids by pump and flow meter and dosing of powders by weight loss feeders. All controlled by the automation and proportional dosing adjusted by frequency control drives. The test plant can be integrated with 3 different PLP coating technologies: DRUM ROTARY; COVER WITH DOUBLE AXLE BLADES; MASS SPIN COATER. ROTARY DRUM The latest development over the more traditional rotary drum, this machine is specially recommended for semi-wet products, small extruded or granulated pellets and lower production capacity. The special corrugated shape of the drum increases the rotation of the product, at the same time protects it from damage and reduces waste inside the machine, making it a perfect machine to be used in food application or with special kibbles for pet food. CONTINUOUS COVER WITH DOUBLE AXLE PADDLES It is our most widely used machine for standard pet food production and has received the majority of R&D improvements during the last years. There are different models that can cover all required production ranges with high liquid inclusion rates or fats. The focus of the machine is the retention time and this is achieved by regulations of speed independent of the axles, internal dampers and automatic check valve in the output of the product. The retention time in standard pet food production it can reach up to 200 seconds. MASS SPIN COATER Compact continuous cover used to add micro liquids up to 1%. The MSC integrates a continuous precision weighing technology, based on Coriolis forces. Thanks to a nozzle special is able to obtain a perfect homogeneity even when the inclusion rates are less than 0.1%. Source: PLP Systems

Preservatives

Preservatives

2+ MIN

10/07/2020

PLP Systems launch Innovative Online Exhibition Stand

Italian dosing and handling specialists, PLP Systems, have recently launched their online exhibition stands, showcasing their latest, innovative solutions for a digital audience. With the continued postponement of trade shows due to COVID-19, many companies have taken to online exhibitions in order to provide customers and industry leaders with an opportunity to better understand their solutions, and PLP Systems have launched a state-of-the-art platform that truly showcases their expert solutions to the market. PLP Systems was founded in 1980, by three friends passionate about the farming sector they grew up in. Through their technological studies, they came to form PLP Systems and innovate the future of liquid and powder dosing systems for a variety of industries. The polished online exhibition and wide variety of solutions on display demonstrate that the company continue to grow and are leading members in the liquid and powder handling sector. The online exhibition stand is categorised into three sections; pet food, feed and aqua feed as well as food equipment. Attendees can explore these sections in detail at a virtual booth and explore the various solutions PLP offer for a variety of processes, ranging from micro-dosing, process hygiene, liquid spraying and pellet coating. One of the most intriguing aspects of their presentation is their new nano-dosing system for animal feeds. PLP's nano-dosing solution, the Nano-DP is designed for dosing very small batches of feed with extreme precision. These products are then forwarded onto the main batch mixer. This solution is ideal for dosing antibiotics and other medicinal materials for feed, as well as low inclusion additives. Should attendees have any questions concerning any of the solutions on offer, contact forms are readily available for them to get in touch with a member of PLP System's expert team. You can access the online exhibition at: mymag.info/e/879 By PLP Systems Source : Milling and Grain