As pet parents spend more time at home, they care more about their pets' health and the food they eat. Instead of feeding them with byproducts and parts of animals that humans do not eat, pet owners increasingly prefer buying high-quality and differentiated food to improve pet nutrition, health, and wellbeing.

Trending products are pet foods that contain a higher portion of quality meat, and innovative products that can solve allergies, picky eating habits, dietary issues. Consumer demand trends create new opportunities for industry players and new investors to innovate, diversify, improve or expand their productions for growth and development.

Although the pet food industry is booming, there are serious issues that pet food producers have to face in the new normal of post-pandemic. The industry is at the risk of severe material and labor shortages as supply chain disruption worse. Production cost inflationary pressure surges with input prices rising amid the historically high energy and raw material costs.

In this context and backed by its global R&D Institutes, Pet Food Business experts, and Sales & Service teams from different regions of the world, FAMSUN held a webinar on pet food solutions at UTC+8:00 of September 30, 2021, and provided the latest insights, new research progress, and improved production practices to support customers grow business in headwinds. Three keynote speakers go straight to the topics that pet food processors are interested in most.

Reducing wastes are the most possible pointcuts to cut costs and improve profitability in a factory. Barry Howard, Vice President of FAMSUN USA Design & Engineering, has over 36 years of experience in pet food factory solutions, focused on Insights on Lean Manufacturing, Lean Factory Layout and Biosecurity. He identified eight deadly wastes generated from transport, inventory, motion, waiting, overproduction, overprocessing, defects, and skills in a factory, and the solution to eliminate these wastes with lean tools.

In terms of food safety in pet food, site, process design, factory design & layout are parts of the key elements in manufacturing safe foods. Barry also introduced how FAMSUN's biosecurity factory solution controls the movements of people, equipment, materials, air, and moisture or condensation in the factory. With the latest zoning design concept, it is possible to prevent recontamination and ensure Food Safety in pet food.

The topic Extruded Pet Food Processing Technology brought by Robert Strathman, President of FAMSUN USA Design & Engineering focused on knowledge and research progress on pet food processing technologies and the data of best production practices. Pet food product & process fundamentals such as bulk density, starch gelatinization, palatability, kibble durability, aesthetics, and shelf life were talked about most in his presentation. In dry pet food processing technology, he focused on pre-conditioning and extruder processes.

Marketplace

High meat pet food is the trending product currently. Robert introduced the most efficient processing technology of high meat pet food, the challenges in processing, and the impact of meat inclusion on production performance

The coating is an indispensable process in pet food production. It allows producers to diversify their products and provide a nutritional, functional, and differentiated experience for pets. Jimmy Wang, an expert of FAMSUN Asia R&D Institute, introduced FAMSUN CYPZ Vacuum Coating Equipment - the company's latest coater that specialized in adding value for pet food products. The machine is featured by consistent and efficient coating and high hygienic standards to produce high quality and food safety. Its successful application stories include the coating production in pet food factories of Japfa, Pure&Natural, FullPET, etc.

Over 70 registers from Europe, Africa, the Middle East, and South Asia participated in the interaction sesión online. They discussed with FAMSUN experts the actual production issues and were well answered. If you have missed the webinar on September 30, you can contact the FAMSUN account manager in your region for the rebroadcast link of this webinar. You are also welcome to follow us in the coming FAMSUN Pet Food Solution webinar series, which FAMSUN plans to host for the convenience of customers in different regions with updated topics and information. Welcome to join us.

Visit www.famsungroup.com for more information.

by Famsun Group

Source: All Pet Food

You could be interested: MASS SPIN COATER - Revolutionary patented system

About company

About company

Office & Factory

Global Presence

Company introduction

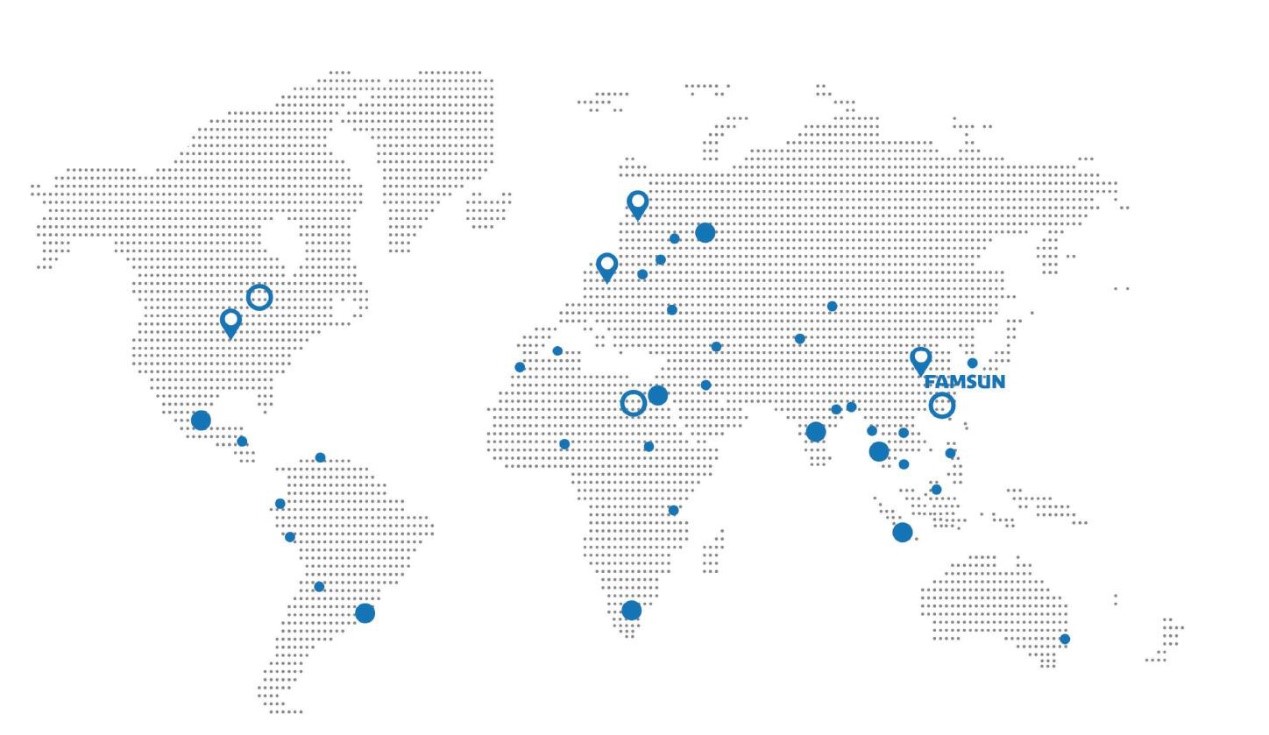

FAMSUN Group Co. Ltd., headquartered in Yangzhou, China, is a global technology partner and the integrated solution provider of plant, equipment, and services in feed manufacturing, grain milling, grain handling and storage, oilseed processing, food processing, steel structure construction, and industrial automation.

FAMSUN has over 2,800 employees, including 900 technicians and engineers. Backed by its strong R&D capabilities, FAMSUN has developed more than 120 series (700 models) of quality feed and grain processing machines and is capable of delivering a wide range of turnkey projects from farm to table and in associated industries.

FAMSUN operates five production sites as well as over 50 agencies, sales & service stations, and spare parts warehouses around the world. FAMSUN has successfully completed over 8,600 referenced projects in more than 140 countries.

Our vision is to provide optimal technology solution and make life better for all. We value innovation, hard work, dedication, integrity, quick response, and team-work.

FAMSUN Pet Food division is committed to machinery research, manufacturing, project engineering, factory construction and integrated solutions in pet food industry, create values for customers. As a leading integrated solution provider in pet food industry, FAMUSN undertakes pet food (dry food, semi-moist, extruded treats) and cat litter turn-key project.

Our corporate leads the market by technology, with experienced elite team and European & USA technical experts, through continuous innovation, to provide customers with professional, safe, systematic extruded pet food production solutions, customized environment-friendly and intelligent factory with high standards, high quality, high efficiency. We won the trust and praise from our partners/customers worldwide.

8,600+ referenced projects in 140+ countries. 50+ agencies, sales & service stations, and spare parts warehouses worldwide closed to customers. Five production bases, one in Egypt and four in China. Total of 74.07 hectares of manufacturing and distribution capacity. 2,800+ employees work in sales, customer service, engineering, R&D, production, and logistics. More than 5% of annual revenue invested in R&D, every year equipment is marked by CE and ATEX sym.

Noticias de la empresa

25/04/2022