Scott, tell us a little bit about your professional career and how you arrived and rose to your current position at Wenger Group.

lived most of my life in Sabetha, Kansas, which has an incredible amount of industry professionals per capita. One of those industries in my hometown happens to be the Wenger Group. Because Sabetha is centrally located among many US pet food producers, I was aware of the pet food industry at a young age. always loved our companion animals and our family currently has three Australian shepherd-husky mix breeds that are truly part of my family. I obtained a mechanical engineering degree from Kansas State University and promptly returned to my hometown. I was an associate at Extru-Tech, Inc. for 32 years gaining knowledge in the various fields of project engineering, international sales, and brand management. I was honored to be appointed as President of Wenger Group in June 2023.

How does your background in the pet food industry help you lead the Wenger Group?

Process Solutions with emphasis on extrusion cooking, drying, coating, and cooling – especially for pet foods and treats – has been a passion for my entire 33-year career. Throughout that time, I've been fortunate to work with some incredibly knowledgeable extrusion cooking experts and some of the most forward-thinking and well-managed pet food producers in the world. From early in my career, I understood the importance of listening intently to understand customer needs, wants, and desires and collaboratively reaching solutions that meet their goals.

Wenger's corporate focus is to provide customers with an 'unparalleled customer experience.' Although Wenger is a well-established and trusted name in the industry, we cannot be content with past success. Our customers face market and competitive challenges, and we must stay ready with updated solutions that can enable our customers to be successful.

What do you think is the current main challenge among Latin American producers?

see a growing opportunity in this region for foods and treats with higher levels of fresh meat content, unique inclusions, and increased palatability. Achieving these types of products requires a more advanced knowledge of extrusion cooking and drying. Our customers can enjoy first-mover advantages by working with nger to produce unique (and higher value) products for their market. Demand for traditional kibble will continue to be strong, but producers who can offer a wider range of foods and treats within a single flexible equipment architecture can be even more successful in Latin America.

Marketplace

How can producers know whether to use twin-screw or single-screw extruders for pet food or treats?

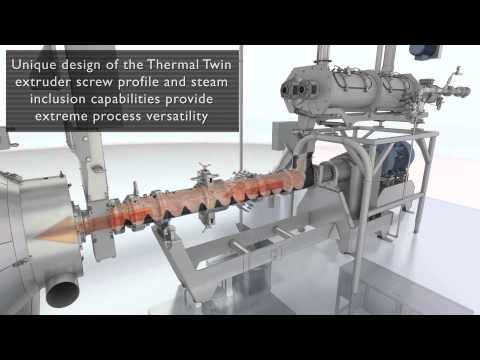

The answer to this starts with knowing the types of desired product characteristics (now and in the future). A single screw extruder is the workhorse in the industry around the globe. They are very effective for high volumes of established products while at the same time offering variability in recipe management. However, if a customer wants to create many different types of foods and treats - with at times even further ingredient and processing flexibility - from the same extruder, then we may suggest twin screw technology. The decision is not about which technology is better because both deliver on metrics all companies measure such as safety, performance, and quality, but rather about the selection of the correct tool to accomplish the customer's current and future states of their business model.

It's also important to note that choosing the right holistic process solution (including drying, coating, cooling, and process controls) should be considered as an equally important decision to that of the extrusion system alone. For that reason, Wenger Group employs many process solution experts who were former customers utilizing extrusion technology. Our Process Group SMEs (subject matter experts) are equipped through education, experience, and frankly the 'school of hard knocks' that provide valuable insight into various available integrated process solutions.

What new initiatives are the Wenger teams focused on?

As part of our overall customer experience initiative, we are focused on technology innovation, manufacturing excellence, and expanding our process knowledge. We are designing and commercializing many offerings including the new PetFLEX™ extrusion system, improved control systems complemented with data analytics, and MES (Manufacturing Execution Systems) overlay for Wenger extruders and dryers. We also have decarbonization modifications for dryers including the use of high temperature heat pumps. In manufacturing, we are implementing processes to decrease lead times while enabling us to use newer, more sustainable materials. Wenger's reputation for extrusion process expertise is well deserved, but we stay diligent in understanding the changing demand for ingredients (including alternative proteins), palatability requirements, shapes, textures, and coatings. As we partner with customers, we try first to understand their needs, wants, and desires – and then we refine and/or recommend processes and hardware accordingly to meet and often exceed those expectations.

How do you support customer Research & Development?

Wenger customers (globally) are constantly developing new products to be successful. Enabling customer R&D has been core to our company for over 60 years, mostly through the Wenger Technical Center, located in Sabetha. For decades, producers of extruded pet food, aquatic feed, and human food have used the Technical Center to confidentially develop new product ideas in a facility with production-scale equipment. This is important because products developed in a small-scale test lab may not translate well into a full-size extrusion system. Plus, at the Technical Center, customers have access to the Wenger process team that can help with ingredient selection, process variables, extrusion parameters, and other critical aspects. We've been told numerous times that the Wenger team helped a customer achieve something they probably couldn't have done on their own at scale and speed to execution. As mentioned earlier, it is woven into our DNA to provide an 'Unparalleled Customer Experience' in all aspects of our business. We are a passionate, caring group that is honored to assist our customers!

What market trends do you see emerging over the next 5 years?

Globally, the trends for pet foods will include more variability in ingredient selection, breed-specific diets, increased palatability, increased nutrition, and treats with unique shapes, colors, and fills that all add to our companion animal's life-long well-being. Pet food producers – like most companies – also have sustainability initiatives and responsibilities that will demand technology solutions that reduce energy usage and are carbon-smart. Processing flexibility & agility will be paramount. Customers want to produce multiple products, with unique ingredients, on the same equipment, and with the same set-up, if possible, to optimize uptime. In other words, producers will increase their product offerings while decreasing production costs. Here at the Wenger Group, we embrace the challenge, and we look forward to working with our customers on these opportunities.

Source: All Pet Food Magazine

You could be interested: The Interview: Daniel Geraldes, Founder of FENAGRA

About company

About company

With a little ingenuity and a lot of hard work, Joe and his brother, Louis Wenger, founded the Wenger Mixing Company in a small town in Kansas (USA) in 1935. They then designed a machine that mixed molasses with dry feed ingredients and thus they began to produce pellets in 1948.

The novel idea of the Wenger brothers created a worldwide industry. Seventy-five years later, Wenger Manufacturing, Inc. remains a family business committed to innovation in the extrusion market.

Today, Wenger offers a range of premium single-screw extruders, twin-screw extruders, dryers/coolers, coating systems, and control systems. A new generation of proud employees work for customer satisfaction in our multiple plants, in our world-class research and development center, and in sales and service offices around the world.

Wenger equipment is unmatched in quality. Perhaps even more important, it is the reputation we have built by having long-lasting partnerships with customers. Lasting because of our dedication, ingenuity, and responsiveness - and our promise to deliver on that commitment for generations to come.