Very early in the morning, Claudio Mathias, Global Director of Sales and Strategy of Maverick – A division of Wenger, picked us up at the hotel located in the Center of Campinas, São Paulo and took us to visit the impressive plant that Wenger and Maverick develop in Brazil, which is worthy of admiration and an example for the whole region.

Although this plant takes place in Brazil, its production covers the entire Latin American region, and even on occasion, it takes care of several orders for equipment intended for the European and Asian markets, a topic that will develop later in this article .

Upon arrival at the plant, Claudio kindly introduced us to Glauber Rodriguez, Director of the faclity and in charge of all manufacturing details of parts and equipments previously commissioned by different companies that bet on such refined quality of equipments.

Once we stepped in the facility we could appreciate the different offices with the personnel in charge of the design of the spare parts, Stock, purchase of raw materials, system department, among other sectors. We sat down and statart a very friendly conversation with Claudio and Glauber, who provide us such important details of both companies, their history and work policy, something inherited from the Wenger brothers more than 75 years after the Company foundation.

The quality, love, professionalism and passion in everything they do comes to light when both Glauber and Claudio tell us how the plant facility and how its production have been growing every year. Although the plant was inaugurated in 2016, since 2019, just at the light of the pandemic that hit the planet, the production of pet food grew and, therefore, the production of equipments and the export of complete lines, not only to the countries of the region, but also to Europe and Asia, due to the high demand the company has in its facility plant from Sabetha Kansas, USA.

Something that caught our attention, in addition to the high level of professionalism, is the implementation of Sustainability within the company's strategy, which is reflected in the purchase of regional components of very high quality that allows the design and production of equipment. with higher levels of energy savings.

Production area

We couldn't help but be amazed at the cleanliness and level of detail that permeated the 10,000 m2 production area, where we could appreciate the focus and passion with which the plant's engineers and experts worked. The spare parts were arranged in such a way that it was impossible not to distinguish each one of them. It help us to check the quality of the steel and the final product.

Marketplace

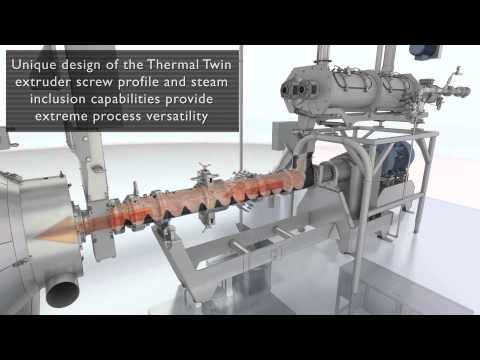

Glauber and Claudio showed us the production of Wenger Horizontal Extruders and Dryers, as well as Maverick Extruders, previously commissioned by various pet food companies. Maverick's proposal is to offer the market a line of standard or modified equipment, keeping the principles of integrity, reliability and quality of Wenger equipment, but with greater flexibility.

The plant not only manufactures equipment and complete lines of pet food, it also produces equipment for aquaculture and human food, although due to the great growth of the Pet industry in recent years, its production represents 70%. According to Glauber, the 84% of pet food manufacturers worldwide own at least one Wenger piece of equipment.

To say Wenger or Maverick is to say quality, efficiency and sustainability and that´s why Marel company recently didn´t hesitate to acquire Wenger Manufacturing LLC., including all the main commercial activities of the group.

According to the company's statement, it was acquired for USD 540 million, although it was agreed to continue the Wenger legacy and its significant impact on the community, as well as Marel shares for Wenger employees.

Marel sees great opportunities and is committed to investing in the combined business to accelerate growth. The acquisition is expected to improve margins and profits. Planned initiatives include expanding manufacturing capacity to meet high demand in Wenger's core markets.

We say goodbye to Glauber, Claudio and the entire team with the satisfaction the Industry counts with a production facility in Latin America for the manufacturing of pet Food equipments of the highest quality, which also has compliance with the highest processing and quality standards that any country of the so-called first world could sign. A pride for our industry that continues to grow steadily, with alliances with Universities and Research Institutes, to achieve the level of excellence in the production of balanced feed in general, and contribute to the nutrition of the different animal species.

Congratulations and Success in the future now hand in hand with Marel, which we´re pretty sure will be able to provide a better service globally, expanding its projects and solutions for the entire feed & food industry and contributing to a great development in terms of energy efficiency, processing and nutrition.

Congratulations and all the best for this example company for the world!

By: Iván Marquetti

All Pet Food

You could be interested: JBT Marel to Host Pet Food Open Day & Seminar in Belgium

About company

About company

With a little ingenuity and a lot of hard work, Joe and his brother, Louis Wenger, founded the Wenger Mixing Company in a small town in Kansas (USA) in 1935. They then designed a machine that mixed molasses with dry feed ingredients and thus they began to produce pellets in 1948.

The novel idea of the Wenger brothers created a worldwide industry. Seventy-five years later, Wenger Manufacturing, Inc. remains a family business committed to innovation in the extrusion market.

Today, Wenger offers a range of premium single-screw extruders, twin-screw extruders, dryers/coolers, coating systems, and control systems. A new generation of proud employees work for customer satisfaction in our multiple plants, in our world-class research and development center, and in sales and service offices around the world.

Wenger equipment is unmatched in quality. Perhaps even more important, it is the reputation we have built by having long-lasting partnerships with customers. Lasting because of our dedication, ingenuity, and responsiveness - and our promise to deliver on that commitment for generations to come.