Wenger Manufacturing, Inc.

https://wenger.com/

Wenger Manufacturing, Inc.

About the company

With a little ingenuity and a lot of hard work, Joe and his brother, Louis Wenger, founded the Wenger Mixing Company in a small town in Kansas (USA) in 1935. They then designed a machine that mixed molasses with dry feed ingredients and thus they began to produce pellets in 1948.

The novel idea of the Wenger brothers created a worldwide industry. Seventy-five years later, Wenger Manufacturing, Inc. remains a family business committed to innovation in the extrusion market.

Today, Wenger offers a range of premium single-screw extruders, twin-screw extruders, dryers/coolers, coating systems, and control systems. A new generation of proud employees work for customer satisfaction in our multiple plants, in our world-class research and development center, and in sales and service offices around the world.

Wenger equipment is unmatched in quality. Perhaps even more important, it is the reputation we have built by having long-lasting partnerships with customers. Lasting because of our dedication, ingenuity, and responsiveness - and our promise to deliver on that commitment for generations to come.

Products

Company News

Extrusion

Extrusion

2+ MIN

05/06/2025

Wenger and Extru-Tech Jointly Unveil EXPRO AI Revolutionizing Extrusion Process Optimization with AI-Powered Insights

Introducing EXPRO AI™: The Future of Extrusion Operations

EXPRO AI™ employs sophisticated AI predictive modeling to analyze historical and real-time process and quality data. By identifying relationships between critical data points, specifications, and operational anomalies, EXPRO AI™ delivers actionable insights that enable manufacturers to predict product quality outcomes and prescribe ideal process setpoints. The result is a significant reduction in process variability and consistently superior product quality.

Key Features and Benefits:

Real-Time Digital Twin Dashboard: Offers real-time situational awareness, empowering operators and managers to make informed decisions on the fly.

Data-Driven Process Optimization: Eliminates guesswork by securely utilizing local data from IIoT devices, historians, and MES systems, ensuring process decisions are based on empirical evidence rather than opinion.

Customized Optimization Models: Tailored solutions per recipe and production line that predict production events.

24/7 Intelligent Operations: Operates continuously without interruptions, serving as an electronic subject matter expert (eSME) that prescribes optimum process parameters for peak performance.

Transforming Industries with Intelligent Manufacturing

EXPRO AI™ is uniquely designed for continuous manufacturing processes and delivers value through improved product yield and quality.

"EXPRO AI™ represents a pivotal advancement in extrusion technology. By leveraging our process expertise and AI based modeling, our clients are able to achieve unprecedented levels of efficiency and product consistency," said Scott Krebs, President of the Wenger Group. "This technology transforms extrusion processes, making them smarter, more adaptive, and highly efficient.

About Wenger

Founded in 1935 in Sabetha Kansas, Wenger Manufacturing is the world's leading supplier of customized extrusion cooking and process systems used to process food, pet food, and aquatic feed. Wenger has offices, manufacturing, and service personnel in the Americas, Europe, and Asia to support customers globally.

About Extru-Tech

With extensive expertise in food, pet food, aquatic feed production, and automated process controls, Extru-Tech serves a global client base. The company provides comprehensive solutions ranging from ingredient handling to extrusion, drying, cooling, coating, and regulatory compliance support.

Contact Information:

Wenger®

15 Commerce Drive

Sabetha, Kansas 66534, USA

Phone: +1 785 284 2133

Email: [email protected]

Website: www.wenger.com

Extru-Tech, Inc.

100 Airport Road

Sabetha, Kansas 66534, USA

Phone: +1 785 284 2153

Email: [email protected]

Website: www.extru-techinc.com

Source: Wenger Group and Extru-Tech Inc.

Market Information

Market Information

1+ MIN

10/01/2025

Wenger Manufacturing Announces Death of Company Patriarch LaVon Wenger

LaVon began his career at Wenger Manufacturing in 1955 after studying engineering at Kansas State University. In 1977, he was named President and led the company, along with his cousin Don, to achieve significant success and global reputation. Through the years, LaVon used his intuition and foresight to develop numerous innovations for extrusion cooking technology - especially for pet food processing. LaVon is the inventor on 44 US patents. LaVon lived his entire life in the town of Sabetha, Kansas USA. This is where Wenger Manufacturing was founded in 1935 and continues as the company's global headquarters today. For decades, LaVon dedicated his time and talents to various community organizations to help Sabetha and neighboring towns become great places to live, work, and raise a family. Scott Krebs, President of Wenger Group, said, 'LaVon's fingerprints are evident each day in the various solutions used by Wenger customers around the world. Many of his pioneering concepts over the years have become today's industry standards. His legacy continues to provide an example for us to be caring, fair, and respectful toward others. We are truly blessed to have known and worked with such a wonderful person and we extend our deepest sympathies to the Wenger family.' About Wenger Founded in 1935, Wenger is the world's leading supplier of extrusion cooking systems for use in food, pet food, and aquatic feed processing. Wenger is a wholly-owned subsidiary of JBT Marel Corporation. Source: Wenger Manufacturing

Interviews

Interviews

5+ MIN

05/08/2024

The interview - Scott Krebs, President of Wenger Group

Scott, tell us a little bit about your professional career and how you arrived and rose to your current position at Wenger Group. lived most of my life in Sabetha, Kansas, which has an incredible amount of industry professionals per capita. One of those industries in my hometown happens to be the Wenger Group. Because Sabetha is centrally located among many US pet food producers, I was aware of the pet food industry at a young age. always loved our companion animals and our family currently has three Australian shepherd-husky mix breeds that are truly part of my family. I obtained a mechanical engineering degree from Kansas State University and promptly returned to my hometown. I was an associate at Extru-Tech, Inc. for 32 years gaining knowledge in the various fields of project engineering, international sales, and brand management. I was honored to be appointed as President of Wenger Group in June 2023. How does your background in the pet food industry help you lead the Wenger Group? Process Solutions with emphasis on extrusion cooking, drying, coating, and cooling – especially for pet foods and treats – has been a passion for my entire 33-year career. Throughout that time, I've been fortunate to work with some incredibly knowledgeable extrusion cooking experts and some of the most forward-thinking and well-managed pet food producers in the world. From early in my career, I understood the importance of listening intently to understand customer needs, wants, and desires and collaboratively reaching solutions that meet their goals. Wenger's corporate focus is to provide customers with an 'unparalleled customer experience.' Although Wenger is a well-established and trusted name in the industry, we cannot be content with past success. Our customers face market and competitive challenges, and we must stay ready with updated solutions that can enable our customers to be successful. What do you think is the current main challenge among Latin American producers? see a growing opportunity in this region for foods and treats with higher levels of fresh meat content, unique inclusions, and increased palatability. Achieving these types of products requires a more advanced knowledge of extrusion cooking and drying. Our customers can enjoy first-mover advantages by working with nger to produce unique (and higher value) products for their market. Demand for traditional kibble will continue to be strong, but producers who can offer a wider range of foods and treats within a single flexible equipment architecture can be even more successful in Latin America. How can producers know whether to use twin-screw or single-screw extruders for pet food or treats? The answer to this starts with knowing the types of desired product characteristics (now and in the future). A single screw extruder is the workhorse in the industry around the globe. They are very effective for high volumes of established products while at the same time offering variability in recipe management. However, if a customer wants to create many different types of foods and treats - with at times even further ingredient and processing flexibility - from the same extruder, then we may suggest twin screw technology. The decision is not about which technology is better because both deliver on metrics all companies measure such as safety, performance, and quality, but rather about the selection of the correct tool to accomplish the customer's current and future states of their business model. It's also important to note that choosing the right holistic process solution (including drying, coating, cooling, and process controls) should be considered as an equally important decision to that of the extrusion system alone. For that reason, Wenger Group employs many process solution experts who were former customers utilizing extrusion technology. Our Process Group SMEs (subject matter experts) are equipped through education, experience, and frankly the 'school of hard knocks' that provide valuable insight into various available integrated process solutions. What new initiatives are the Wenger teams focused on? As part of our overall customer experience initiative, we are focused on technology innovation, manufacturing excellence, and expanding our process knowledge. We are designing and commercializing many offerings including the new PetFLEX™ extrusion system, improved control systems complemented with data analytics, and MES (Manufacturing Execution Systems) overlay for Wenger extruders and dryers. We also have decarbonization modifications for dryers including the use of high temperature heat pumps. In manufacturing, we are implementing processes to decrease lead times while enabling us to use newer, more sustainable materials. Wenger's reputation for extrusion process expertise is well deserved, but we stay diligent in understanding the changing demand for ingredients (including alternative proteins), palatability requirements, shapes, textures, and coatings. As we partner with customers, we try first to understand their needs, wants, and desires – and then we refine and/or recommend processes and hardware accordingly to meet and often exceed those expectations. How do you support customer Research & Development? Wenger customers (globally) are constantly developing new products to be successful. Enabling customer R&D has been core to our company for over 60 years, mostly through the Wenger Technical Center, located in Sabetha. For decades, producers of extruded pet food, aquatic feed, and human food have used the Technical Center to confidentially develop new product ideas in a facility with production-scale equipment. This is important because products developed in a small-scale test lab may not translate well into a full-size extrusion system. Plus, at the Technical Center, customers have access to the Wenger process team that can help with ingredient selection, process variables, extrusion parameters, and other critical aspects. We've been told numerous times that the Wenger team helped a customer achieve something they probably couldn't have done on their own at scale and speed to execution. As mentioned earlier, it is woven into our DNA to provide an 'Unparalleled Customer Experience' in all aspects of our business. We are a passionate, caring group that is honored to assist our customers! What market trends do you see emerging over the next 5 years? Globally, the trends for pet foods will include more variability in ingredient selection, breed-specific diets, increased palatability, increased nutrition, and treats with unique shapes, colors, and fills that all add to our companion animal's life-long well-being. Pet food producers – like most companies – also have sustainability initiatives and responsibilities that will demand technology solutions that reduce energy usage and are carbon-smart. Processing flexibility & agility will be paramount. Customers want to produce multiple products, with unique ingredients, on the same equipment, and with the same set-up, if possible, to optimize uptime. In other words, producers will increase their product offerings while decreasing production costs. Here at the Wenger Group, we embrace the challenge, and we look forward to working with our customers on these opportunities. Source: All Pet Food Magazine

Extrusion

Extrusion

1+ MIN

04/01/2024

Brian Streit has returned to Wenger as Senior Vice President–Innovation & Process Solutions.

After 15 years in milling and pet food manufacturing, Brian joined Wenger in 2012 as Director of Pet Food & Aquatic Technology and represented Wenger for 10 years. During those years, Brian became well known in the Pet Food and Aquatic Feed industries for his process knowledge and creative problem solving, helping numerous customers globally develop new products and refine their manufacturing processes. Now back with Wenger, Brian will work across multiple business units within the Wenger Group with intentional customer-centric strategy focused on the needs, wants & desires of our customer base. Please join us in welcoming Brian to the Wenger Group leadership team. Source: All Pet Food

Extrusion

Extrusion

2+ MIN

26/05/2023

Scott Krebs appointed President of Wenger

In this position, Scott will drive strategic objectives and lead the Wenger team in the US, Denmark, Brazil, and all other countries. In close collaboration with the Marel leadership team, he will drive cross-selling of Marel solutions to customers in the Plant, Pet, and Feed business segment. 'I am very excited to welcome Scott to the role of President of Wenger. Scott has more than 30 years of experience in the field of extrusion technology and is well-known and respected for his many great achievements within Wenger, especially leading the successful build-up and growth of Extru-Tech, a company that is part of Wenger. With Scott on board, we ensure a continuation of the successful Wenger strategy and that we continue to strengthen our position and customer relationships in the Plant, Pet, and Feed business segment', says Arni Sigurdsson, Chief Business Officer and Deputy CEO. Scott joined Wenger in June 1991 and has since had a long and admirable career within Wenger, from an entry position as Project Engineer to the most recent executive role of President, Extru-Tech, a subsidiary of Wenger, focused on extrusion systems to produce human food, pet food, aquatic feed, and animal feed products. Scott has demonstrated excellent customer focus, operational and people leadership, and P&L management, and has been instrumental in building and improving the competitive position of Extru-Tech, resulting in more than 50% of profitable topline revenue coming from aftermarket services. Scott holds a bachelor's degree of Science in Mechanical Engineering from Kansas State University, and he lives in Sabetha, Kansas, US, with his family. On this occasion, Marel would also like to extend a special and personal thank you to Jesper Hjortshøj for his dedication and valuable contribution in leading Wenger as interim President since the acquisition in July 2022. Jesper will continue to support Scott and the Wenger team during the transition and return his full focus to his leadership role as VP of Business Development at Marel. A standalone platform for new and attractive growth markets Wenger will operate as a standalone business division and leverage Marel's global reach and digital solutions to grow and expand the business. Marel will provide strategic direction and is committed to invest in the business and manufacturing capacity to drive commercial synergies and accelerate growth. Wenger enjoys a diversified and loyal customer base ranging from blue-chip pet food processors to startup companies in plant-based proteins. Over 60% of Wenger's revenues derive from pet food, where the company has a leading global position, and over 40% of revenues come from aftermarket services. This has resulted in Wenger's healthy profitability with an EBIT margin of 14-15%, strong cash flow and solid return on invested capital. Q3 2022 was the first quarter where the newly acquired Wenger business was consolidated in Marel's segment reporting under the name of 'Plant, Pet and Feed,' which also included Marel's own sales of retail and food service solutions into this market segment. By Marel All Pet Food

Market Information

Market Information

4+ MIN

29/12/2022

Wenger Manufacturing Brazil – A model facility in Latin America

Very early in the morning, Claudio Mathias, Global Director of Sales and Strategy of Maverick – A division of Wenger, picked us up at the hotel located in the Center of Campinas, São Paulo and took us to visit the impressive plant that Wenger and Maverick develop in Brazil, which is worthy of admiration and an example for the whole region. Although this plant takes place in Brazil, its production covers the entire Latin American region, and even on occasion, it takes care of several orders for equipment intended for the European and Asian markets, a topic that will develop later in this article . Upon arrival at the plant, Claudio kindly introduced us to Glauber Rodriguez, Director of the faclity and in charge of all manufacturing details of parts and equipments previously commissioned by different companies that bet on such refined quality of equipments. Once we stepped in the facility we could appreciate the different offices with the personnel in charge of the design of the spare parts, Stock, purchase of raw materials, system department, among other sectors. We sat down and statart a very friendly conversation with Claudio and Glauber, who provide us such important details of both companies, their history and work policy, something inherited from the Wenger brothers more than 75 years after the Company foundation. The quality, love, professionalism and passion in everything they do comes to light when both Glauber and Claudio tell us how the plant facility and how its production have been growing every year. Although the plant was inaugurated in 2016, since 2019, just at the light of the pandemic that hit the planet, the production of pet food grew and, therefore, the production of equipments and the export of complete lines, not only to the countries of the region, but also to Europe and Asia, due to the high demand the company has in its facility plant from Sabetha Kansas, USA. Something that caught our attention, in addition to the high level of professionalism, is the implementation of Sustainability within the company's strategy, which is reflected in the purchase of regional components of very high quality that allows the design and production of equipment. with higher levels of energy savings. Production area We couldn't help but be amazed at the cleanliness and level of detail that permeated the 10,000 m2 production area, where we could appreciate the focus and passion with which the plant's engineers and experts worked. The spare parts were arranged in such a way that it was impossible not to distinguish each one of them. It help us to check the quality of the steel and the final product. Glauber and Claudio showed us the production of Wenger Horizontal Extruders and Dryers, as well as Maverick Extruders, previously commissioned by various pet food companies. Maverick's proposal is to offer the market a line of standard or modified equipment, keeping the principles of integrity, reliability and quality of Wenger equipment, but with greater flexibility. The plant not only manufactures equipment and complete lines of pet food, it also produces equipment for aquaculture and human food, although due to the great growth of the Pet industry in recent years, its production represents 70%. According to Glauber, the 84% of pet food manufacturers worldwide own at least one Wenger piece of equipment. To say Wenger or Maverick is to say quality, efficiency and sustainability and that´s why Marel company recently didn´t hesitate to acquire Wenger Manufacturing LLC., including all the main commercial activities of the group. According to the company's statement, it was acquired for USD 540 million, although it was agreed to continue the Wenger legacy and its significant impact on the community, as well as Marel shares for Wenger employees. Marel sees great opportunities and is committed to investing in the combined business to accelerate growth. The acquisition is expected to improve margins and profits. Planned initiatives include expanding manufacturing capacity to meet high demand in Wenger's core markets. We say goodbye to Glauber, Claudio and the entire team with the satisfaction the Industry counts with a production facility in Latin America for the manufacturing of pet Food equipments of the highest quality, which also has compliance with the highest processing and quality standards that any country of the so-called first world could sign. A pride for our industry that continues to grow steadily, with alliances with Universities and Research Institutes, to achieve the level of excellence in the production of balanced feed in general, and contribute to the nutrition of the different animal species. Congratulations and Success in the future now hand in hand with Marel, which we´re pretty sure will be able to provide a better service globally, expanding its projects and solutions for the entire feed & food industry and contributing to a great development in terms of energy efficiency, processing and nutrition. Congratulations and all the best for this example company for the world! By: Iván Marquetti All Pet Food

Market Information

Market Information

6+ MIN

28/04/2022

Marel to acquire Wenger, a global leader in processing solutions for pet food, plant-based proteins, and aqua feed

The acquisition of Wenger is a platform investment into new, complementary and attractive growth markets for Marel and will form the fourth business segment alongside poultry, meat and fish. The acquisition is subject to customary closing conditions such as anti-trust and approval of Wenger's shareholders. Platform acquisition adding a fourth business segment to Marel, in addition to poultry, meat and fish, and pro-forma, expected to contribute around 10% of Marel's total revenues and 12% of EBITDA. Highly complementary product portfolios and geographic presence with Wenger's industry-leading extrusion and dryer technology focused on the high growth markets of pet food, plant-based proteins and aqua feed. Founded in 1935, Wenger has 500 employees and revenues in 2022 are expected to be USD 190 million, EBITDA USD 32-35 million, and EBIT margin 14-15%. Total investment for the acquisition is USD 540 million and the transaction multiple corresponds to 14x EV/EBITDA adjusted for expected tax benefits of USD 60-70m. Pro-forma leverage following completion of the acquisition is estimated at around 3x net debt to EBITDA, in line with Marel's targeted capital structure of 2-3x net debt to EBITDA. The acquisition is fully in line with Marel's 2017-2026 growth strategy which targets 12% average annual increase in revenue through a balanced mix of organic and acquired growth. New business segment to become a fourth pillar of the business model A new business segment, based on the Wenger platform, will constitute Marel's fourth pillar alongside poultry, meat and fish, and will be focused on the sizeable and attractive growth markets of pet food, plant-based proteins and aqua feed. On a pro-forma basis, this new business segment will account for around 10% of Marel's total revenues and 12% of combined EBITDA. This new growth platform is an important addition to Marel's product portfolio to meet customers' rising demand for high-quality food and feed that is processed in a sustainable and affordable way. The two companies have a great strategic and cultural fit with highly complementary product portfolios and geographic presence, creating a strong platform to enhance further growth. Wenger shares Marel's passion for innovation and commitment to best-in-class products, backed by an experienced team and long-standing partnerships with customers. Wenger enjoys a diversified and loyal customer base ranging from blue-chip pet food processors to startup companies in plant-based proteins. This has resulted in healthy profitability, strong cash flow and solid return on invested capital. Capitalizing on Marel's global reach and digital platform, the two companies are well positioned to explore future growth opportunities together. Growth platform into new and attractive growth markets The global petfood and aqua feed markets are estimated at over EUR 100 billion and EUR 50 billion respectively and growing at 5-6% annually. The plant-based protein market is currently around EUR 7 billion and expected to grow 15-20% annually. The addressable market for Marel and Wenger in solutions and services within pet food, plant-based proteins and aqua feed is estimated to be around EUR 2 billion with expected annual growth of 4-6%, in line with Marel's long-term market growth expectations. Marel aims to grow faster than the market, based on its continuous innovation and global reach. Throughout the years, Marel has gradually expanded its playing field and is now the only pure-play provider of full-line solutions, software, and services to the poultry, meat, and fish industries. In the vision solidified in 2016, the scope was widened from the three animal proteins to focus more generally on transforming food processing. In 2020, Marel announced an increased focus on adjacent markets and in 2021 it formally established a business development division focused on pet food and plant-based proteins. Adding Wenger's strong capabilities in that area, Marel is accelerating its journey and is well positioned to capitalize on providing transformational solutions to the large and attractive growth markets of pet food, plant-based proteins, and aqua feed. Marel sees great opportunities and is committed to invest in the combined business to accelerate growth. The acquisition is expected to be margin and earnings enhancing. Planned initiatives include expanding manufacturing capacity to respond to high demand in Wenger's core markets. Aftermarket revenues represent over 40% of Wenger's revenues, and Marel's global reach and digital platform will support a more proactive aftermarket approach to better service customers around the world. Transaction highlights and timeline Marel has agreed to acquire Wenger Manufacturing LLC., including all relevant business activities of the group. The total investment for the acquisition is USD 540 million. Thereof, USD 530 million is the purchase price on a cash and debt-free basis (enterprise value). The remaining USD 10 million is a combination of a contribution to a not-for-profit private foundation, to continue the legacy of Wenger and its meaningful impact on the community, as well as Marel shares for Wenger employees. The purchase price will be paid with cash at hand and existing credit facilities. Discussion with selling shareholders regarding partial consideration in Marel shares is ongoing and will be concluded prior to closing. The transaction will also result in expected tax benefits of USD 60-70 million and the adjusted transaction multiple corresponds to around 14x EV/EBITDA. The acquisition will be financed through Marel's strong balance sheet and existing credit facilities. To preserve operational headroom, Marel has signed a EUR 150 million bridge facility from BNP Paribas Fortis SA/NV. Assuming a full cash payment, pro-forma leverage following completion of the acquisition is estimated to be around 3x net debt/EBITDA, compared to Marel's targeted capital structure of 2-3x net debt/EBITDA. The closing of the acquisition is subject to customary closing conditions, including anti-trust and shareholder approval of Wenger, which is expected to take place during Q2 2022. Arni Oddur Thordarson, CEO of Marel, commented: 'We are thrilled to join forces with the great team in Wenger with whom we have a strong strategic and cultural fit. Wenger's passion for innovation and commitment to high-quality solutions, in addition to their excellent customer focus and talent management, are the key attributes Marel is proud to partner with. Wenger is a true leader in its field of providing solutions and services to the pet food industry and aqua feed industries, and has in recent years made its mark on the fast-growing plant-based protein consumer market with best-in-class solutions positioned right in the center point of the value chain. The Wenger acquisition is in line with our vison of a world where food is produced sustainably and affordably. Throughout the years, Marel has gradually expanded its playing field. This platform acquisition will add the fourth business segment to our business model, in addition to the poultry, meat and fish segments, where we are a global leader in processing solutions, services and software. On a proforma basis, the new segment will account for around 10% of revenues and 12% of combined EBITDA. We see immediate opportunities for growth and value creation by leveraging Marel's global reach and digital platforms in Wenger's sizable addressable markets. The two companies have complementary technologies and a product portfolio that will accelerate the journey to become full-line providers in the respective fields. Marel has a strong financial position to pursue future growth avenues and a proven track record in driving long-term value creation. I am confident Marel will be a good steward for the Wenger business, its talented team and continued local community engagement, and we remain committed to our continued future success.' Trevor Angell, Chairman of the Board of Directors of Wenger, commented: 'Wenger has a long history as an innovative, responsive partner to our customers. The relationships we have built, and the incredible character of our people are central to this. Our long-standing customers worldwide are looking for a trusted partner and local support to keep their operations running at optimal performance. Marel has invested significantly in its global reach and digital platform, which will improve Wenger's ability to be the partner of choice for our clients throughout the long life-cycle of our equipment. Further, our dedicated team will be joining a large, healthy, international organization where they can grow and see increased opportunities. During our interaction, it was apparent that there is great strategic and cultural alignment between Wenger and Marel. Our shared values and vision, our care for customers and employees, and the combined technical strengths of the two companies will create tremendous value in global food production. We are pleased to be joining forces with Marel, and we are excited for the opportunities our friends and teammates will experience.' Source: Marel

Extrusion

Extrusion

1+ MIN

19/10/2020

Magnum ST Extruder by Wenger Manufacturing

The Magnum ST Series by Wenger Manufacturing redefines versatility for smaller extruders, with no loss of capacity. The ability to use higher Specific Mechanical Energy (SME) settings to take extruded products to the next level makes this solution especially innovative.

Wenger's extruder boasts speeds of up to 1,200rpm and power levels to 165kW hr/t SME at volumetric capacity. Benefits of the Magnum ST Extruder include potential for lower bulk density, higher absorbency levels of liquid coating, smaller cell structure, enhancement of textural properties and higher cook levels.

by All Extruded

Interviews

Interviews

5+ MIN

10/09/2020

Interview with Mr. Ed de Souza, Extrusion Systems Process Director of Wenger Manufacturing

Ed de Souza graduated with a degree in Agribusiness at Fort Hays University in Kansas, USA in 1995. He also obtained a master's degree in Business Administration, with a focus on business management at Fundação Getúlio Vargas.

Mr de Souza was hired by Wenger Manufacturing Inc in late 1995. Working at Wenger for the past 24 years, he has developed an extensive know-how in food extrusion processing. He has worked in food extrusion research at the Wenger Technical Centre in Sabetha, Kansas, and has knowledge also as a field service technician working with equipment start-ups, process troubleshooting and providing lectures and training.

How did you come to be involved in this industry?

After graduating with a degree in Agribusiness at Fort Hays University in Kansas, USA, I was interviewing with two multinationals in the commodities business, paperwork related to work visas halted these processes. By chance, I went to visit Sabetha, Kansas, the headquarters for Wenger Manufacturing, Inc., with a college friend, before I returned to Brazil, my home country. At a local high school football game, I met with the service manager for South America and the rest is history. I landed in this business by chance and I believe it was meant to be, as I fell in love with extrusion processing right away.

What has been your proudest achievement, whilst working at Wenger? Has the company expanded greatly since you have been part of the team?

In 2000, my US work visa expired, and I had to make the decision to move to a different country. Brazil was, at the time, a great market and at full expansion for pet food and aquatic feeds. Our customers needed local support and parts, so I was proud to help starting Wenger conduct business in Brazil.

Firstly, our Brazilian office served as a service office and soon after we moved in manufacturing parts and then equipment, before evolving into a full blown modern manufacturing plant in 2013. It is an honour being a founder of Wenger within Brazil and representing Wenger Manufacturing, Inc. I consider this to be a great achievement in my career and, yes, the company has expanded greatly since I have been part of this proud team at this honourable company and I have so much to be thankful for.

What are the biggest challenges for your industry, and how do Wenger combat and resolve these issues?

The extrusion industry faces challenges that are often overlooked. Most extruded aquafeed manufacturers focus too much on cost accounting, and there is a fine life between being cost effective and losing throughput and product quality. If these areas were focused on, as they are key for product improvement and financial gain, then manufacturers could process better products in larger quantities, using a lot less resources:

Raw Materials: Investing a small percentage in formulation cost to provide extrusion friendly ingredients, such as better starch sources and functional proteins, can possibly double the throughput of an extrusion line, using essentially the same fixed assets and fixed cost.

Hardware: Reduced capital investment for inferior standard and or inappropriately engineered and configured grinding, extrusion and drying equipment can result in a continued higher processing cost and lower throughput for the life of the equipment, resulting in higher use of resources due to inefficiency. The lack of proper asset maintenance, which is preventive as opposed to corrective, is a major road block for efficiency and output quality on an extrusion line. Proper preventive maintenance is the very essence of asset preservation: it prolongs the life of productive equipment at a minimum cost, as well as preserving the output quality and ensures reliability.

Asset maintenance, especially with extrusion cooking equipment, should not be considered as a lump sum that needs to be reduced in the budget of next year, rather it needs to be viewed as crucial key performance indicator and analysed as cost-per-tonne. In most cases, a planned preventive maintenance programme will represent less than two percent of the total production cost but, if neglected, it can result in throughput loss, product quality decline and loss of clientele.

The third topic that serves as a challenge for the industry is control of the processing system. When the two prior points are well managed, process personnel need to be able to precisely control the process for ensuring high quality output on an extrusion line. Processing software has the ability to offer user friendly process tools that ensures a smoother extrusion process and the highest quality product, as well as the ability to provide data for managers to assess and carry out corrective decisions.

Wenger has developed and continues to improve its processing equipment, namely extruders and dryers, to provide a user friendly and durable state-of-the-art solution, and modern processing tools overcome ingredient variations and other potential hurdles. Through years of know-how and process engineering, Wenger offers a comprehensive and precise process control automation by our one and only Automated Process Control system (APM™). Wenger values what is best for our clients.

You recently took part in the Aqua Feed Extrusion Conference and gave a great presentation concerning operational excellence leadership. How do Wenger incorporate these leadership techniques to ensure your company remain at the peak of the processing industry?

Wenger focus on providing all-inclusive process support, in addition to advanced extrusion equipment and modern processing control tools. One of our most appraised support systems, Wenger CARE™, improves our customer´s operations, generating more quality products with the least resources spent.

What do you see as a possible challenge that the industry may face over the next five years, and how will your company play a part in prevention or solving it?

The COVID-19 pandemic presents interesting opportunities. I believe we will see an increased consumption of cultivated fish, due to its minimised impact on the environment and increased number of people adopting pets, as well as extruded plant protein derivatives as an alternative nutrition for humans. We are ready with superior technology for the three area we specialise in: State-of-the-art and advanced extrusion equipment for pet food, aquatic feeds and human food.

Has COVID-19 affected business in any way for Wenger? How has the company overcome these challenges?

We have seen challenges, primarily brought about through the limitations on travelling, but, on other hand, we have developed new and improved tools for remote access for client interaction, equipment commissioning and client support.

What makes your company stand out from its competitors? Do you have any projects or plans that we should look out for over the coming year from you and your company?

What we focus on is the customers' best interests. Our vision is simply to be the best partner our clients can attain. This vision represents our commitment to state-of-the-art and advanced extrusion solutions and innovative processes utilised via expert support. We are also very focussed on research and development. We are, just now, renovating and substantially improving our 55-year old extrusion research centre in Sabetha, Kansas, refining it in terms of both size and technology, making sure our customer stands out from the competition, right from day one and use just the minimum of the earth´s resources.

by Perendale Publishers

Extrusion

Extrusion

3+ MIN

10/06/2020

Wenger Technical Centre Expansion and Renovation on track for 2020 On-time Completion

Aerial photography reveals steady progress on the construction with the new concrete foundations, stem walls and floors providing a visual for what the perimeter of the new tech centre will look like. The new construction will make the facility more scalable and extend its lifespan long into the future. The modernisation will include enhancing preventative measures for food safety, and the added square footage will make the centre more versatile. Expansion of the world-renowned Wenger Technical Centre in Sabetha, KS, USA, is keeping pace and hitting construction milestones, even in the face of obstacles created by the COVID-19 pandemic. 'The pandemic has not disrupted plans or impeded progress with the upgrade,' says Brend King, Vice President and Technical Centre Director. 'We have excellent momentum—construction of the new building is hitting every milestone while the Technical Centre is still fully operational inside.' Work already was well underway on the $13 million renovation when COVID-19 abruptly forced businesses to shift operations protocols. The new building is being constructed around the old—the modernised, tension fabric structure will completely enclose the existing facade. That original steel structure then will be taken down, revealing capacity that is 40 percent larger and able to fit full-scale, commercial versions of nearly every piece of equipment Wenger manufactures. The new structure is scheduled for completion in July and demolition of the old building will begin in August. While the pandemic did slow progress slightly at the beginning, Mr King says they've amended schedules when needed and have been recouping lost time as work moves along. Meanwhile, testing and R&D projects continue inside the building, though protocols have been modified due to COVID-19. Wenger clients depend on the Technical Centre as a low-risk testing environment for new products and processes. 'Clients need us to continue functioning so they can meet their objectives, and we are committed to remain open and operational during this unpredictable time,' Mr King says. 'Our ingenuity drives us, and with persistence and flexibility we've found ways to work around the COVID-19 curveballs and stay open for business.' For the time being, Wenger is unable to allow customers physically in the facility, but the team shares photos and video and provides detailed data sheets to show customers how the extruders and formulations are set up. They also send samples of the end product. 'Thankfully, this is temporary,' Mr King says. 'Customers have been very understanding and cooperative with these less-than-ideal, but necessary, changes to protocol. We're tremendously proud and grateful to have earned trust in the industry so that clients are comfortable letting us conduct runs on their behalf,' Mr King says. And in those instances where clients must be present, Wenger has shifted projects to a timeframe when restrictions are loosened. Justin Moore, Extrusion Coordinator for Companion Animals and Aquafeed, and Topher Dohl, Extrusion Coordinator for Human Food and Industrial, have focused on scheduling and communication with customers to keep them apprised and meet everyone's needs. Mr King says the shuffling of schedules has opened up time to focus on Wenger R&D projects, allowing the team to gather data to validate assumptions and theories. 'We've made some incremental steps on R&D processes we've been working on internally—and we look forward to sharing these exciting innovations.' It also has allowed Wenger to finish internal projects early to leave more time for client projects pushed to a later date. The general contractor PMI Nebraska LLC, along with CL Construction of Lincoln, Neb., worked through difficult weather and muddy conditions this winter and spring to keep the project pushing forward. Wenger also is working with Pinnacle Electric, PCI Mechanical, Schenck Process, Scott Equipment and IPS on various aspects of the project. As for COVID-19 precautions, Wenger is following public health expert advice and implementing measures related to social distancing, hand washing, and sanitising high-touch areas. They take temperatures in the morning and limit contact among employees. 'Safety is always a top priority at the Technical Centre, pandemic or not; and because many of our processes deal with food products, our standard safety practices match up well with public health guidelines for COVID-19,' Mr King says. 'It was easy to build social distancing measures onto the sound health and safety practices we already had in place.' by Perendale Publishers

Extrusion

Extrusion

1+ MIN

15/04/2020

Live Webinar Series- Wenger Manufacturing

In times like these, we must all learn new ways to reinvent ourselves. When everyone is advising us to stay 6-ft apart, we need to find opportunities to be now more connected than ever before, yet being apart. With that in mind, we have proudly designed a season of webinars to help maintain the connection and relationship flow with our clients and future clients, through what we do best, besides state-of-the-art extruders and dryers, by mentoring and educating through science and R&D. This series of webinars will happen weekly for 4 weeks in a row and will provide insights to a very trendy topic in the food industry, which Wenger has been a key value-adder on for nearly 50 years now: Textured Plant Proteins - How, what they're made of and more; long-term advice in order you take away your own next competitive edge plan. We're fortunate to be almost sold out in less than 24 hours. The new era starts on April 23rd - 10AM Central US & Canada. Tune in! Wenger Manufacturing, Inc.

Extrusion

Extrusion

2+ MIN

22/03/2020

Wenger Manufacturing Announces Multimillion-Dollar Expansion of Innovation and Development Centre

Wenger Manufacturing, Inc, has begun work on a US $13 million renovation project to expand and modernise the Wenger Technical Centre in Sabetha, USA. The Wenger Technical Centre is a facility dedicated to innovation and continuous improvement of extrusion process systems for food, feed and industrial applications.

The Wenger Technical Centre houses full-scale extruders, dryers and ancillary components to provide a real-world development environment for extrusion-based products and processes. A recognised proving ground for innovation and training, the centre is used by clients, academia and other industry partners for accelerating product development and operational training.

'This renovation is a strategic reinvestment into a facility that has long served our industries as the critical hub for innovation and continuous improvement,' says Lafe Bailey, Co-CEO and President of Sales and Corporate Development. 'The Technical Centre has held global importance to the extrusion industry since 1954, and we are committed to both renewing, and expanding, the roles and responsibilities that the Wenger Technical Centre holds in the industries we serve.'

The new construction will increase the existing 22,000-square-foot centre's capacity by 40 percent, making the facility more scalable and extending its lifespan long into the future. The modernisation will include enhancing preventative measures for food safety, and the added square footage will make the centre more versatile. It will expand the scope of market-facing services while also further enhancing existing innovation projects already active in the Wenger pipeline.

'As our industries face increased scrutiny over food safety, the new Wenger Technical Centre will provide a lowrisk environment to evaluate prototypes and make sure new products and processes adhere to safety and quality standards,' says Brend King, Vice President and Technical Centre Director.

'We're very excited for this expansion as it will allow us to continue helping clients—and Wenger—move ideas from concept to market more quickly.'

by Wenger Manufacturing

Extrusion

Extrusion

4+ MIN

26/11/2019

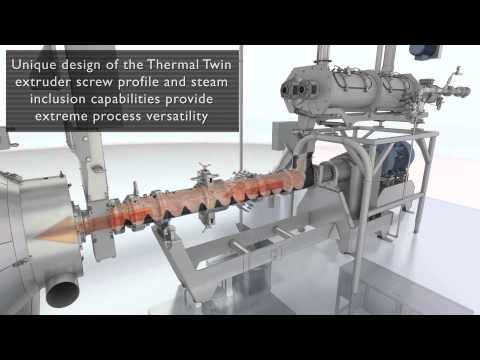

Twin Screw Extrusion

Wenger revolutionises twin screw extrusion with unique models dedicated to pet food and aqua feeds Traditional twin-screw extrusion design has served its purpose as the pet food and aqua feed industries developed. Yet both industries now stand at a tipping point where new trends are pushing the traditional systems beyond their limit. Flexibility is key and what the new generation Wenger twin screw extrusion systems are built on. The Thermal Twin® extrusion system is tailored for pet food manufacturers, so they can develop a wider range of products using an extensive choice of ingredients while preserving ingredient and product identity. The Aquaflex® extrusion system is tailored for aquatic feed manufacturers to maximise their investment by giving them the capability to manufacture a wide range of products such as floating, sinking, shrimp, and micro feeds in different product sizes while utilising a broad ingredient selection. This flexibility is possible given these systems are engineered with a specialised screw profile design to deliver higher volumetric capacity and the capability to operate using a wide range of thermal and mechanical energy cooking conditions. Thermal and mechanical energy are the main energy sources utilised in the extrusion process. A review of current extrusion processes in the industry indicates the ratio of consumed thermal to mechanical energy ranges from 1:1 to 2:1. This ratio determines utility costs as well as maintenance costs, specifically the costs to replace worn rotating elements. A recent study compared energy input and operating cost for three extrusion system (See Table 1). It was observed that even though the total energy input (thermal + mechanical) was higher for a thermal twin screw extrusion system, it was less expensive to operate over time compared to a standard single screw and twin-screw extrusion system. An extrusion system with the ability to vary this energy utilisation ratio and shift to the most favorable energy sources from a cost standpoint, brings increased flexibility to the cost of operating the system. Wenger extruders are engineered to operate in thermal to mechanical energy ratios from 1:1 to as much as 14:1. This is achieved with a twin-screw profile that allows up to four-to-six times more steam injection into the extruder barrel. Additionally, these systems are coupled with a high intensity preconditioner (HIP) which provides less product moisture variation and increases the starch gelatinisation compared to other steam conditioning designs (See Table 2). As a result of a wider energy utilisation ratio and a specialised twin screw profile, coupled with a preconditioner which delivers less product moisture variation and increased cook, the flexibility of the Thermal Twin® and Aquaflex® extrusion systems become key to increase product offerings. Thermal energy is considered a more natural way of cooking when compared to mechanical energy. This translates to less shear and more gentle kneading to continuously develop the visco-elastic dough product matrix. With a Thermal Twin® extrusion system, pet food manufacturers can go beyond the traditional dry expanded and offer high carb, baked, soft moist, vegetable bit inclusion, and high meat pet food. Furthermore, specialty treats (short and long), retort-stable wet food, engineered ingredients (up to 200% percent% wet meat slurry content), and textured vegetable/meat protein products can be manufactured with this type of system. With an Aquaflex® extrusion system, aqua feed manufactures can expand their offering to shrimp, floating, micro, sinking, and fish soluble inclusion feed. New generation twin screw extruder design and thermal cooking allow for a wider ingredient utilisation such as novel animal and vegetable protein sources. Not only is there a wider ingredient selection to work with, inclusion levels of ingredients such as fresh meat and slurries are two-fold in new generation Wenger twin screws extruders when compared to single screw and traditional twin-screw extrusion systems. Higher inclusion levels suggest all animal protein could be supplied in the form of fresh meat for pet food and fish slurries for aqua feed instead of rendered meals, which translates to premium, clean label products. Additionally, product appearance (smoother surface), palatability, digestibility, and ingredient retention rates are enhanced when quality fresh ingredients are processed using a new generation twin screw extrusion system. A recent case study in pet food palatability showed higher consumption ratio and first choice preference with pet food manufactured with a new generation extrusion system compared to traditional extrusion platforms. Nutritional studies in Brazil, Europe, and the United States indicate that there is less protein degradation and lower fat rancidity levels when thermal energy is emphasised over mechanical energy during the extrusion process. Protein digestibility of up to 95 percent was observed for product generated on a Thermal Twin® extrusion system using fresh meat compared to 80-85 percent protein digestibility of a product using rendered meat meals. Additionally, significant higher retention rate of important ingredients when thermal energy inputs are emphasised (See Table 3). In two separate case studies in India and Vietnam using a new generation twin screw Aquaflex® extrusion system, a 10 percent formula cost reduction was observed producing shrimp feed and tilapia feed without compromising product integrity. Pellet durability indices above 99 percent were recorded in both studies, where product size ranged from 0.6 mm up to 2.2 mm in shrimp feed and 1.8 mm up to 7.0 mm in tilapia feed. Additionally, an average equipment wear cost of US$1.05/mton was achieved using the new generation twin screw. Significantly lower compared to a single screw (US $2.10/mton) and traditional twin-screw extrusion system (US$3.41/mton). Overall, the new generation twin screw extrusion systems simply outperform the single screw and traditional twin-screw systems. The flexibility that has been engineered into these extrusion systems supplies pet food and aqua feed manufacturers the precise tool to maximise their investment and optimise cost of operation. Moreover, it can help achieve premiumisation and clean label products by allowing a wider range and higher inclusion level of fresh ingredient utilisation. by Adrian Martinez-Kawas, PhD, Wenger Manufacturing

4+ MIN

04/11/2019

Twin Screw Extrusion

Wenger revolutionises twin screw extrusion with unique models dedicated to pet food and aqua feeds Traditional twin-screw extrusion design has served its purpose as the pet food and aqua feed industries developed. Yet both industries now stand at a tipping point where new trends are pushing the traditional systems beyond their limit. Flexibility is key and what the new generation Wenger twin screw extrusion systems are built on. The Thermal Twin® extrusion system is tailored for pet food manufacturers, so they can develop a wider range of products using an extensive choice of ingredients while preserving ingredient and product identity. The Aquaflex® extrusion system is tailored for aquatic feed manufacturers to maximise their investment by giving them the capability to manufacture a wide range of products such as floating, sinking, shrimp, and micro feeds in different product sizes while utilising a broad ingredient selection. This flexibility is possible given these systems are engineered with a specialised screw profile design to deliver higher volumetric capacity and the capability to operate using a wide range of thermal and mechanical energy cooking conditions.Thermal and mechanical energy are the main energy sources utilised in the extrusion process. A review of current extrusion processes in the industry indicates the ratio of consumed thermal to mechanical energy ranges from 1:1 to 2:1. This ratio determines utility costs as well as maintenance costs, specifically the costs to replace worn rotating elements. A recent study compared energy input and operating cost for three extrusion system (See Table 1). It was observed that even though the total energy input (thermal + mechanical) was higher for a thermal twin screw extrusion system, it was less expensive to operate over time compared to a standard single screw and twin-screw extrusion system. An extrusion system with the ability to vary this energy utilisation ratio and shift to the most favorable energy sources from a cost standpoint, brings increased flexibility to the cost of operating the system. Wenger extruders are engineered to operate in thermal to mechanical energy ratios from 1:1 to as much as 14:1. This is achieved with a twin-screw profile that allows up to four-to-six times more steam injection into the extruder barrel. Additionally, these systems are coupled with a high intensity preconditioner (HIP) which provides less product moisture variation and increases the starch gelatinisation compared to other steam conditioning designs (See Table 2). As a result of a wider energy utilisation ratio and a specialised twin screw profile, coupled with a preconditioner which delivers less product moisture variation and increased cook, the flexibility of the Thermal Twin® and Aquaflex® extrusion systems become key to increase product offerings. Thermal energy is considered a more natural way of cooking when compared to mechanical energy. This translates to less shear and more gentle kneading to continuously develop the visco-elastic dough product matrix. With a Thermal Twin® extrusion system, pet food manufacturers can go beyond the traditional dry expanded and offer high carb, baked, soft moist, vegetable bit inclusion, and high meat pet food. Furthermore, specialty treats (short and long), retort-stable wet food, engineered ingredients (up to 200%% wet meat slurry content), and textured vegetable/meat protein products can be manufactured with this type of system. With an Aquaflex® extrusion system, aqua feed manufactures can expand their offering to shrimp, floating, micro, sinking, and fish soluble inclusion feed. New generation twin screw extruder design and thermal cooking allow for a wider ingredient utilisation such as novel animal and vegetable protein sources. Not only is there a wider ingredient selection to work with, inclusion levels of ingredients such as fresh meat and slurries are two-fold in new generation Wenger twin screws extruders when compared to single screw and traditional twin-screw extrusion systems. Higher inclusion levels suggest all animal protein could be supplied in the form of fresh meat for pet food and fish slurries for aqua feed instead of rendered meals, which translates to premium, clean label products. Additionally, product appearance (smoother surface), palatability, digestibility, and ingredient retention rates are enhanced when quality fresh ingredients are processed using a new generation twin screw extrusion system. A recent case study in pet food palatability showed higher consumption ratio and first choice preference with pet food manufactured with a new generation extrusion system compared to traditional extrusion platforms. Nutritional studies in Brazil, Europe, and the United States indicate that there is less protein degradation and lower fat rancidity levels when thermal energy is emphasised over mechanical energy during the extrusion process. Protein digestibility of up to 95 percent was observed for product generated on a Thermal Twin® extrusion system using fresh meat compared to 80-85 percent protein digestibility of a product using rendered meat meals. Additionally, significant higher retention rate of important ingredients when thermal energy inputs are emphasised (See Table 3). In two separate case studies in India and Vietnam using a new generation twin screw Aquaflex® extrusion system, a 10 percent formula cost reduction was observed producing shrimp feed and tilapia feed without compromising product integrity. Pellet durability indices above 99 percent were recorded in both studies, where product size ranged from 0.6 mm up to 2.2 mm in shrimp feed and 1.8 mm up to 7.0 mm in tilapia feed. Additionally, an average equipment wear cost of US$1.05/mton was achieved using the new generation twin screw. Significantly lower compared to a single screw (US $2.10/mton) and traditional twin-screw extrusion system (US$3.41/mton). Overall, the new generation twin screw extrusion systems simply outperform the single screw and traditional twin-screw systems. The flexibility that has been engineered into these extrusion systems supplies pet food and aqua feed manufacturers the precise tool to maximise their investment and optimise cost of operation. Moreover, it can help achieve premiumisation and clean label products by allowing a wider range and higher inclusion level of fresh ingredient utilisation. by Adrian Martinez-Kawas, PhD, Wenger Manufacturing All Extruded

Home

Home

1+ MIN

09/10/2019

Wenger - Seminar on 'Food Extrusion: Cereals, Protein & Other Ingredients'

Wenger Manufacturing orginezed an excellent Seminar on 'Food Extrusion: Cereals, Protein & Other Ingredients' (Formally Texturized Vegetable Protein and Other Soy Products) was presented last week at Tees Research.

This program covered detailed information on cereal grains, legumes, soy protein, dry extrusion; full fat soybean processing; extrusion-expelling of soybeans for making natural/organic soy flour; raw material selection, preparation and characteristics of soy flour, concentrates and isolates; extrusion hardware, single and twin screw extruders for cereals and TVP production; extrusion dies; extruder trouble shooting effect of preconditioning; wheat gluten and its application; thermal and mechanical processing of cereal grains, high protein, whole grain products, coating of cereals and snacks, application of TVP in meat, meat products, vegetarian application; quality control and testing of finished products; high moisture meat analogs, soy flavor, drying, toasting of food products, dry milling of cereals.

The demonstrations included producing natural/organic soy flour using extruder and expeller, TVP production by single and twin-screw extruders, fibrous soy protein, high moisture meat analog sorghum based whole grain cereals, coating cereals and flavoring TVP products, and several others.

We invite you to the Next Seminar!! Don´t Miss it!!

by All Extruded